Overview of Petro-refinery burners and Their Use in Industrial Furnaces

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Boilers serve as fundamental components in heating systems, supplying the thermal energy essential for a range of industrial and commercial applications. The burner, as the

In today’s world, energy conservation reducing environmental pollution are top priorities across various industrial sectors. Burners, as the central components of industrial furnaces and boilers,

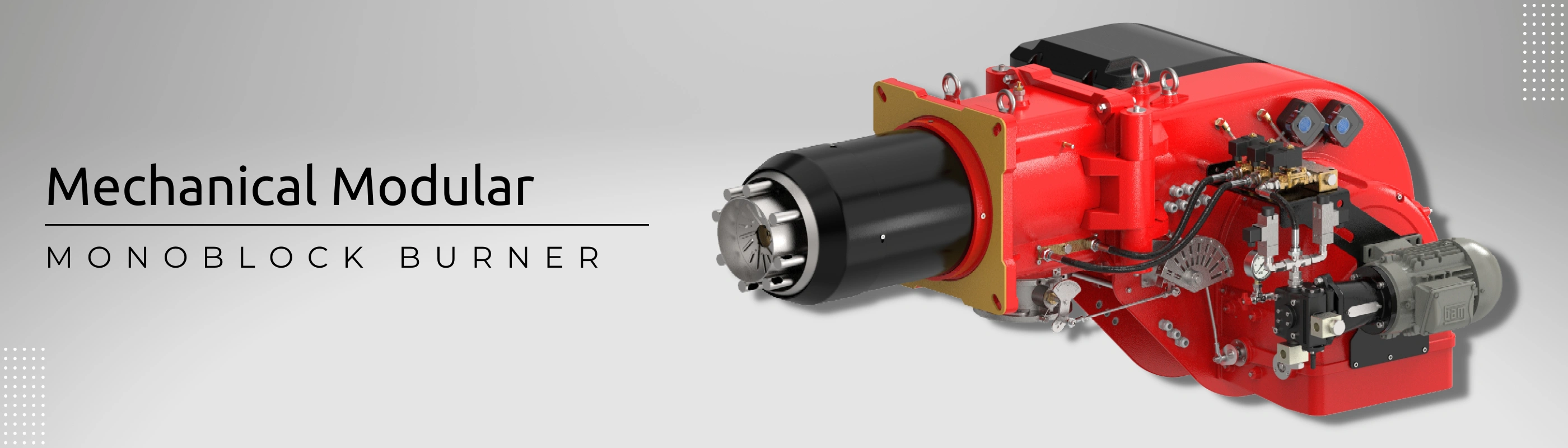

RGB-MC series of burners cover a firing range from 1000 to 6000 kW, and they are manufactured with high-quality electro/mechanical accessories with easy installation and commissioning. They are mechanically resistant and are economically designed for city or industrial applications such as three-pass hot water boilers, steam boilers, hot air generators, etc.

Their operation is “two-stage” at the oil side and “modulating” at the gas side with the installation of a PID logic regulator and respective probes. The customers should kindly note that the PID regulator is not included in the burners routine process and should be ordered separately.

RGB-MC series burners guarantee high-efficiency levels in all the various applications, thus reducing fuel consumption and running costs. Optimization of sound emissions is guaranteed by the special design of the air suction circuit and the use of soundproofing material. The exclusive design ensures reduced dimensions, simple use, and maintenance. A wide range of accessories guarantees elevated working flexibility.

Raadman gas and dual fuel burners are suitable for the following utilization.

The following methods of regulation are available for RGB-MC and RLGB-MC Series burners:

Oil: Two-stage operation

Gas: Two-stage progressive or modulating operation, with a specific kit (PID regulator and related temperature or pressure sensors.)

Designed in accordance with ISIRI-7595 and ISIRI-7594 Iran national standards (equal to the BS-EN676, and BS-EN267 European standards).

Air humidity: max. 80 % relative humidity, no condensation.

The combustion air must be free of aggressive substances (halogens, chlorides, etc.) and impurities (dust, debris, vapours, etc.).

The emissions have been measured in various models at the maximum output, according to DIN-EN 676 and DIN-EN 297 standards.

The values of CO and NOx during burner operation are lower than 30 and 120 mg/kWh at 20 % excess of air for normal versions and, lower than 20 and 80 mg/kWh for Low NOx versions (LN series). consequently, the burner’s NOx class of II and III is reported and being approved for normal version and LN Versions respectively.

LN versions (Low Nox Burners) have a higher rate of mixing during their operation. This results in a further decrease in the flame length and an increase in the flame diameter.

The flame dimensions which play an effective role in the burner efficiency and influence their compatibility with the boiler combustion chamber geometry, are presented in the above diagram.

The Raadman burners can be appropriately selected for all boilers which are designed according to the BS-2790, BS-855, EN-303, and BS-EN 12953-3. It is recommended that a flame fill 90% of combustion chambers at its maximum output.

Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners Electrical Modular Burners

Newsletter