Overview of Petro-refinery burners and Their Use in Industrial Furnaces

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Boilers serve as fundamental components in heating systems, supplying the thermal energy essential for a range of industrial and commercial applications. The burner, as the

In today’s world, energy conservation reducing environmental pollution are top priorities across various industrial sectors. Burners, as the central components of industrial furnaces and boilers,

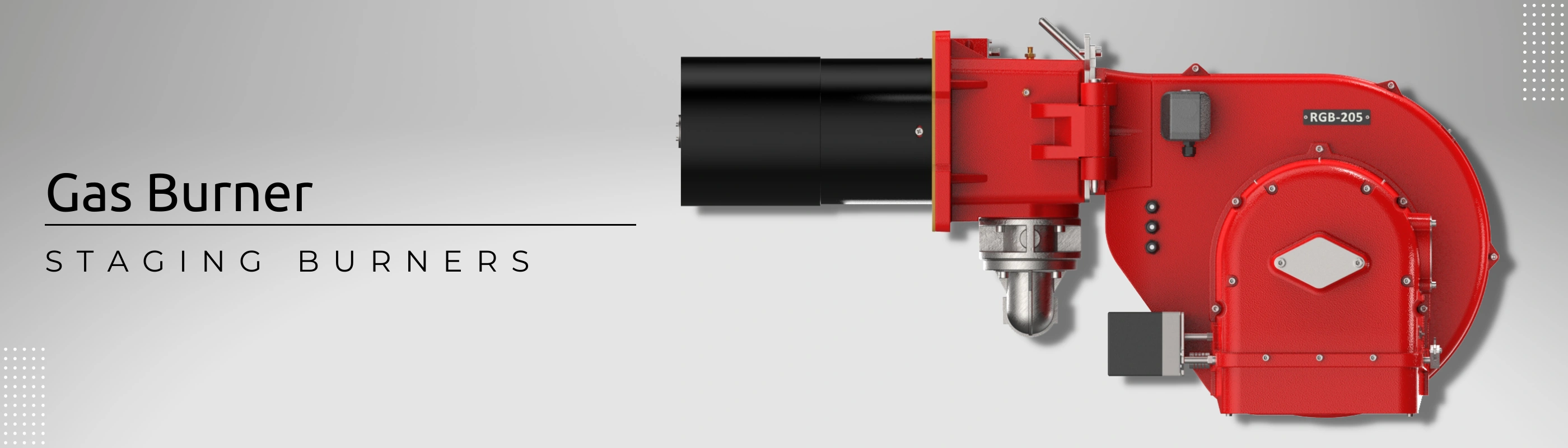

Working diagram for gas burner certified in accordance with EN 676.

The firing rate diagram has been obtained considering ambient temperature of 20°C and atmospheric pressure of 1013 mbar (Sea level condition). For installation at higher altitudes, a reduction in capacity of 1% per 100 m above sea level should be taken into account.

Newsletter