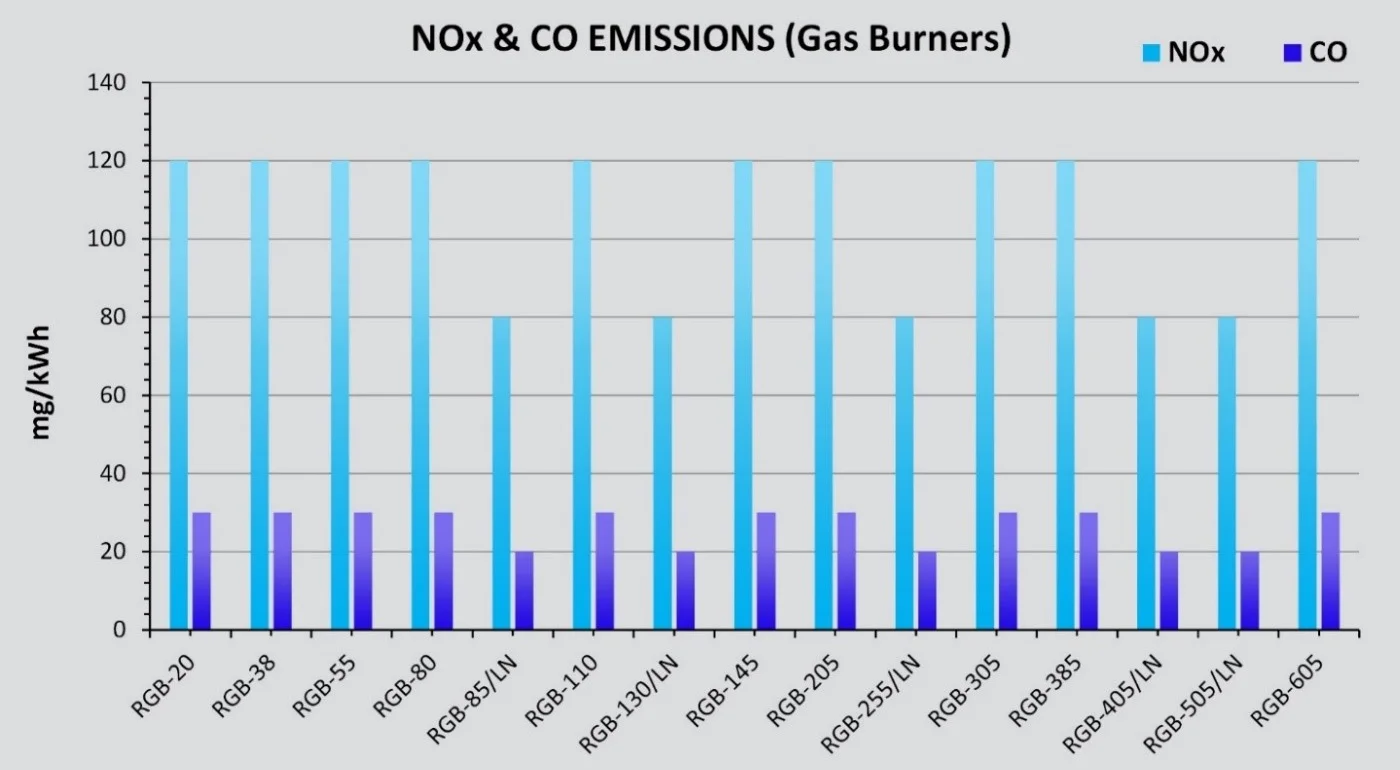

Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

Home / MonoBlock Burner (MB Series) / Staging Burners / Gas Burners / Page 2

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

During the last century, Nitrogen oxide emissions, called NOx, have constantly been increasing. Due to the destructive effects of nitrogen oxides on the health of

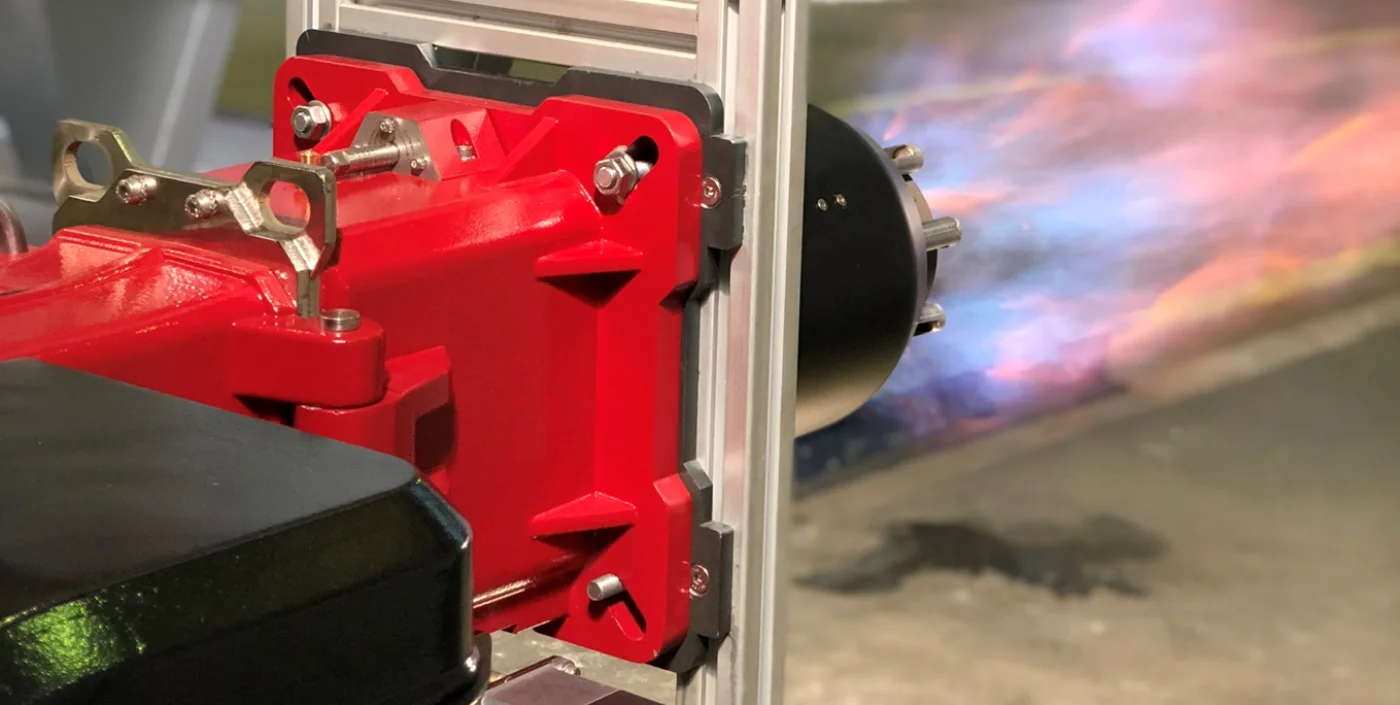

The «furnace industry» and products determine the type of flame contact. In many heat treatment processes, where the combustion gases must not come into contact

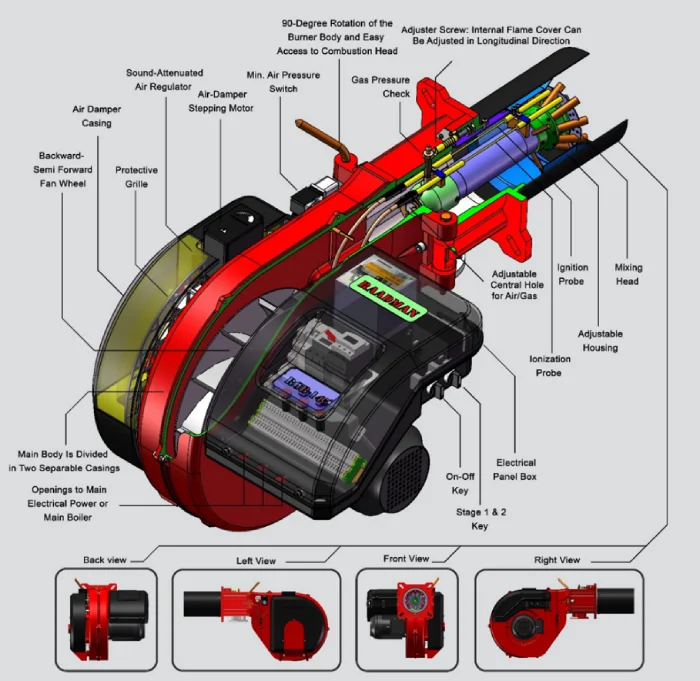

Working diagram for gas burner certified in accordance with EN 676.

The firing rate diagram has been obtained considering ambient temperature of 20°C and atmospheric pressure of 1013 mbar (Sea level condition). For installation at higher altitudes, a reduction in capacity of 1% per 100 m above sea level should be taken into account.

PACKMAN Company was established in February, 1975. The company has started its activity in the field of producing High-Pressure Vessels such as Hot-Water Boilers, Steam Boilers, Pool Coil Tanks, Softeners and Heat Exchangers since 1984.

Newsletter