Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

During the last century, Nitrogen oxide emissions, called NOx, have constantly been increasing. Due to the destructive effects of nitrogen oxides on the health of

The «furnace industry» and products determine the type of flame contact. In many heat treatment processes, where the combustion gases must not come into contact

Raadman gas and dual fuel burners are suitable for the following utilization.

Designed in accordance with ISIRI-7595 and ISIRI-7594 Iran national standard (equal to the BS-EN676, and BS-EN267 European standards).

The following methods of regulation are available for Raadman-Staging (Monoblock) burners:

Gas/oil: Two or Three stages of operation

Air humidity: max. 80 % relative humidity, no condensation.

The combustion air must be free of aggressive substances (halogens, chlorides, etc.) and impurities (dust, debris, vapours, etc.)

The emissions have been measured in various models at the maximum output, according to DIN-EN 676 and DIN-EN 297 standards.

The values of CO and NOx during burner operation are lower than 30 and 120 mg/kWh at 20 % excess of air for normal versions and, lower than 20 and 80 mg/kWh for Low NOx versions (LN series). consequently, the burner’s NOx class of II and III is reported and approved for normal version and LN Versions respectively.

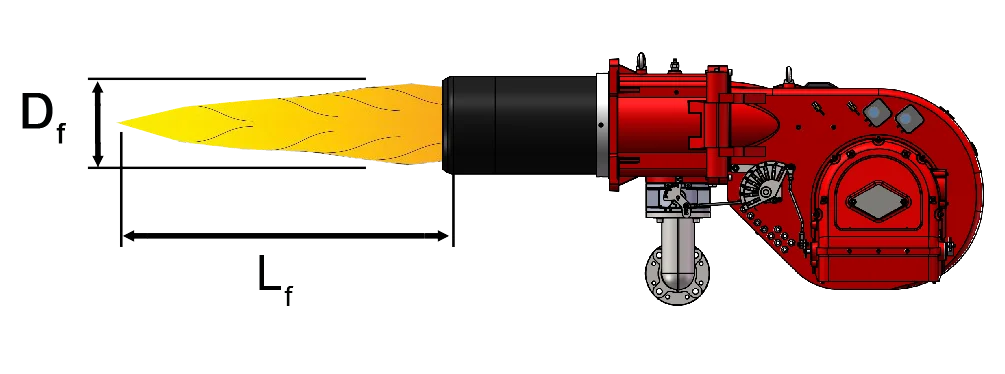

LN versions have a higher rate of mixing during their operation. This results in a further decrease in the flame length and an increase in the flame diameter.

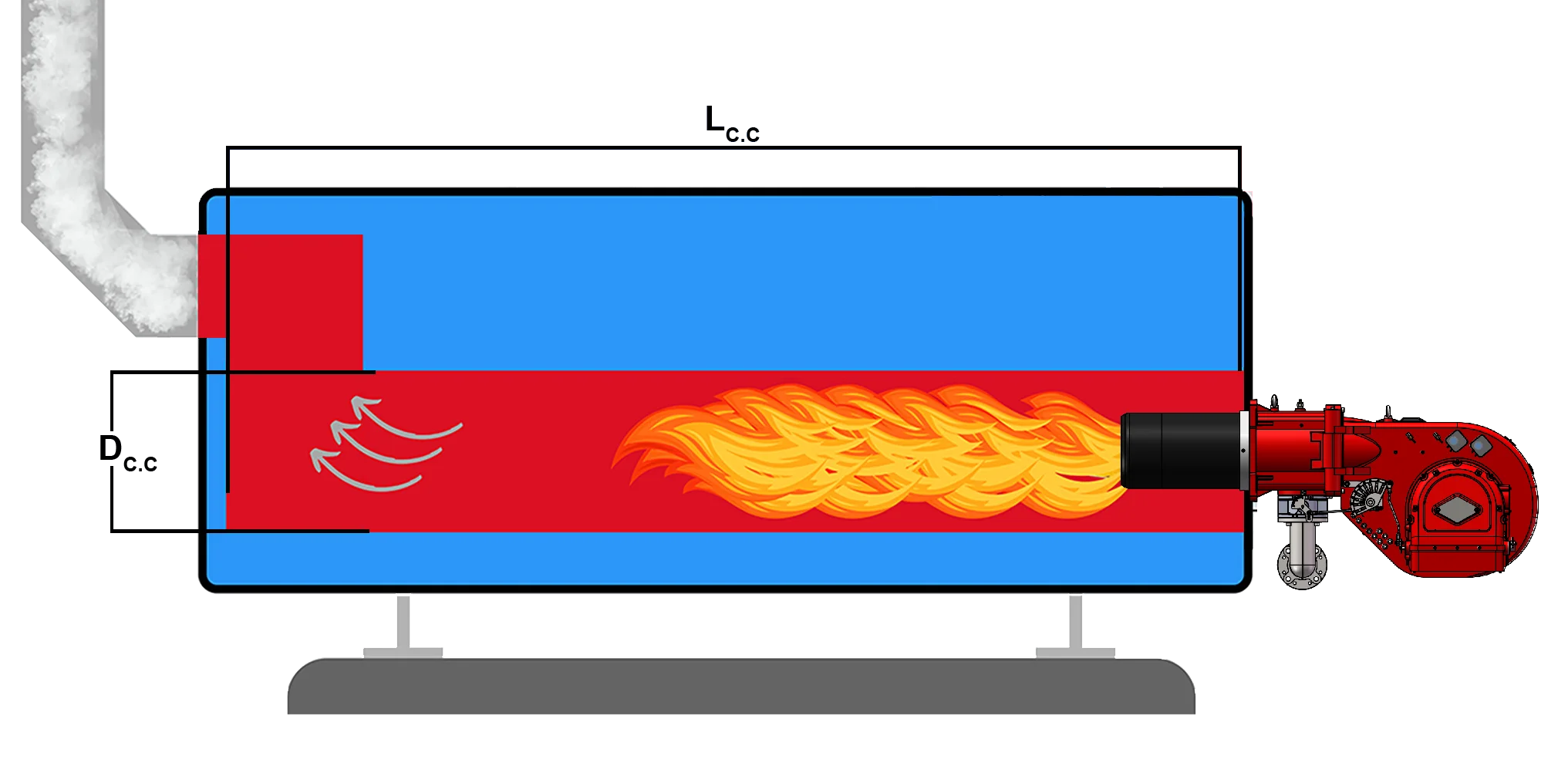

The flame dimensions which play an effective role in the burner efficiency and influence their compatibility with the boiler combustion chamber geometry, are presented in the above diagram.

The Raadman burners can be appropriately selected for all boilers which are designed according to the BS-2790, BS-855, EN-303, and BS-EN 12953-3. It is recommended that a flame fill 90% of combustion chambers at its maximum output.

According to the BS-EN 676, the valve proving system shall be used in burners with a capacity above 1.2 MW. Consequently, MADAS-MTC10 or DungsVDK200 valve-proving systems are highly recommended.

On boilers with hinged doors, the valve train must be mounted on the opposite side of the boiler door hinges.

Break points in the valve train should be provided to enable the door of the heat generator to be swung open. The main gas line is best separated at the compensator.

The valve train should be properly supported in accordance with the site conditions. See the Raadman accessories list for various valve train support components.

staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner staging burner

PACKMAN Company was established in February, 1975. The company has started its activity in the field of producing High-Pressure Vessels such as Hot-Water Boilers, Steam Boilers, Pool Coil Tanks, Softeners and Heat Exchangers since 1984.

Newsletter