Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and the need

Share This Post

The term “NOx” has been appeared in several articles, but many individuals may not know what it is. NOx (nitrogen oxides) is a harmful pollutant which is emitted during the combustion of fossil fuels such as natural gas or diesel. It has very destructive effects on planet and living things. NOx is measured in terms of mg/kW or ppm. Flue Gas Recirculation (FGR) is recommended by scientists and engineers to reduce the emission of this pollutant. It will be explained in more details in this article.

NOx is the representative of nitrogen oxides (NO and NO2) in combustion process of fossil fuels such as natural gas or diesel. This pollutant is expressed in terms of mg/kW.h or ppm. The NOx caused by combustion is entered to the environment through the boiler chimney. It has very harmful effects on global warming, causes acid rain and diseases, and depletes ozone layer. “Flue Gas Recirculation” means returning the combustion products into a new combustion cycle with the aim of NOx reduction. The scientific and practical effects of this process have been explained in this article and practical solutions have been provided.

In studies conducted by the World Health Organization in 2015, the annual costs caused by pollution, which lead to disease and death, were estimated 1.6 trillion dollars in the European Union. The role of NOx along with carbon monoxide is very obvious. This is despite the fact that environmental standards are stricter in European countries compared to third world countries. In September 26, 2018, European Union announced that the amount of nitrogen dioxide in water heaters must not exceed 56 mg for fuel consumption per kwh due to the harmful effects of this pollutant. Accordingly, Greater London Authority (GLA) established rules in which the maximum allowable NOx emission limit for gas heating systems was announced to be 40 mg/kWh. After successful projects in implementation fields in countries such as Germany and Denmark, the environmental requirements regarding the NOx and carbon monoxide limits became a law in the Paris Treaty (or the 2020 Treaty), a treaty that obliges all the involved countries (including Iran) to refine pollution situation by 2020. Packman Company, as one of the pivotal manufacturers of hot water and steam boilers in Iran, has been trying to take a step in improving the NOx effects in alignment with NOx global requirements.

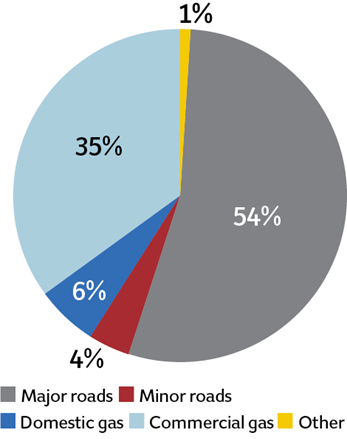

NOx is emitted by different industries such as automobile, cooking, heating systems, and etc. Heating systems with gas fuel have a share of 35% in this regard. The NOx caused by natural gas combustion generally comes from three sources: thermal NOx, fuel NOx, and prompt NOx.

Figure 1. sources of NOx in London

It is formed at the temperature above 1200° C due to the oxidation of nitrogen and air. This NOx, which plays the largest share in natural gas fuel production, depends on two factors: the combustion temperature and duration that nitrogen molecule is at this temperature. The higher the flame temperature, the higher the possibility of nitrogen molecular breakdown and the more thermal NOx is produced.

It is formed when the nitrogen in fuel is in the vicinity of the combustion air. The share of fuel NOx is not high in natural gas but it is remarkable in liquid fuels such as diesel and solid fuels such as coal.

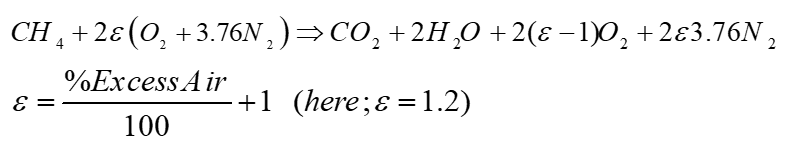

this NOx which is obtained in the first stage of combustion, is caused when the nitrogen in the atmosphere reacts with oxygen radicals in the air. The oxygen radical is formed when the oxygen molecule splits into two oxygen atoms with unpaired electrons. The amount of this NOx is not significant compared to the other two types. According to these points, the important factor for NOx emission for gas fuel is thermal NOx. Parameters such as the amount of excess combustion air, the flame temperature and the possibility of air and gas mixing in the burner head are the most important factors affecting the thermal NOx for gas fuel.

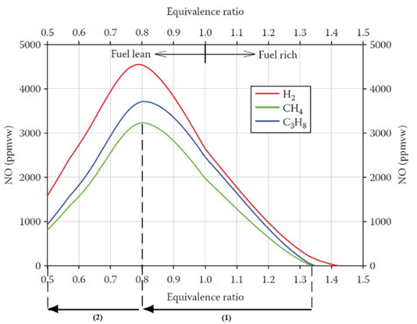

Figure 2- the NOx caused by methane and propane combustion in terms of equivalent ratio

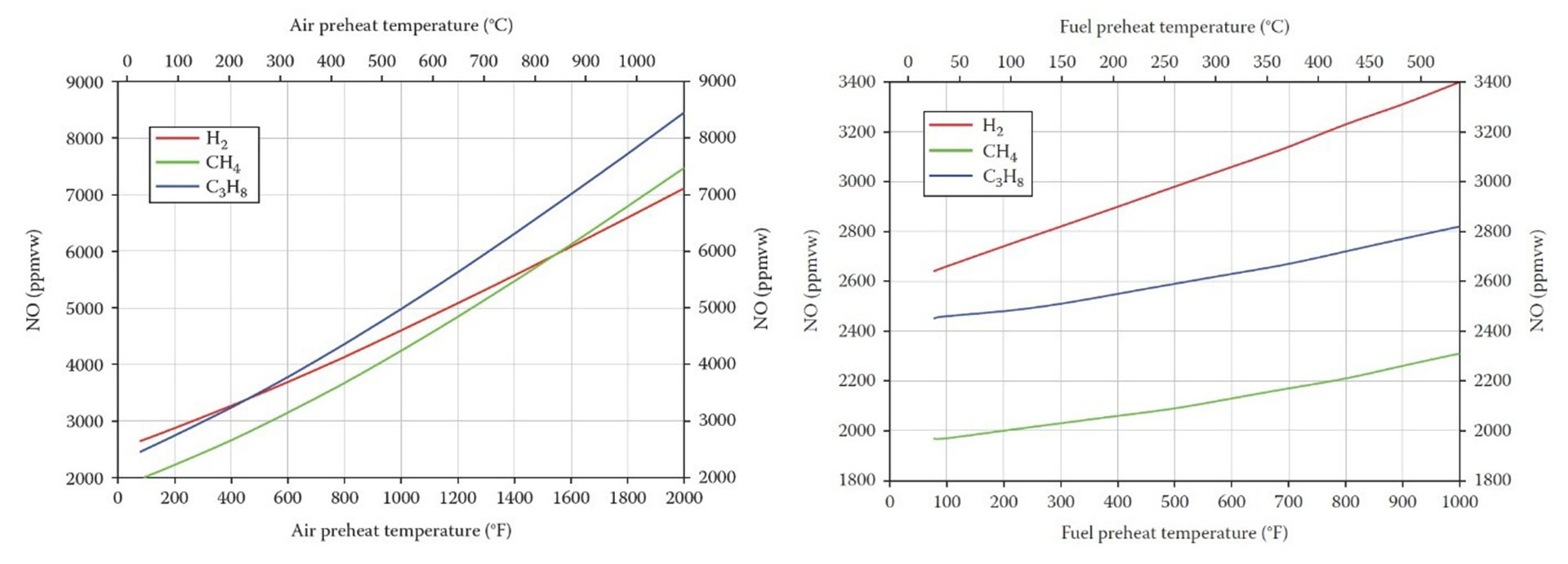

The amount of NOx emission caused by combustion, in terms of equivalent ratio, is shown in Figure 2. The equivalent ratio is the result of the fraction of actual fuel to stoichiometric fuel and the values more than 1 means that the actual fuel is higher than the stoichiometric fuel which is called fuel rich. The values less than 1 indicate the fuel lean. In common conditions that the combustion air is more than fuel and combustion is single-stage, the equivalent ratio is less than 1. When the excess combustion air is low and close to zero (around the stoichiometric equivalence point as shown in Figure 2), NOx emission is at minimum. The reason is lack of extra oxygen to be reacted with nitrogen atom. With increasing excess air, the amount of NOx emission is gradually increased until it reaches the highest point of the graph. After that, with increasing excess air (more than 30%) NOx is reduced which is caused by decreasing the flame temperature. Therefore, in the processes whose combustion is not staging, reducing the excess air will have significant effects on combustion. Although air and fuel preheating cause NOx emission and a rise in flame temperature, it causes the recirculation of heat from the boiler chimney, improvement of the general efficiency of boiler, and reduction of carbonic pollution.

Figure 3- preheating effects on NOx emission for Methane and Propane

In this method that is the main topic of this article, by adding neutral gases such as carbon dioxide, nitrogen, steam or … to the combustion site, the average flame temperature and consequently the thermal NOx will be decreased. One of the perfect sources of neutral molecules is the combustion products passing through the boiler chimney which has lower temperature compared to the combustion chamber. By adding or recirculating 10% of the combustion products, it is possible to reduce the flame temperature by 7%.

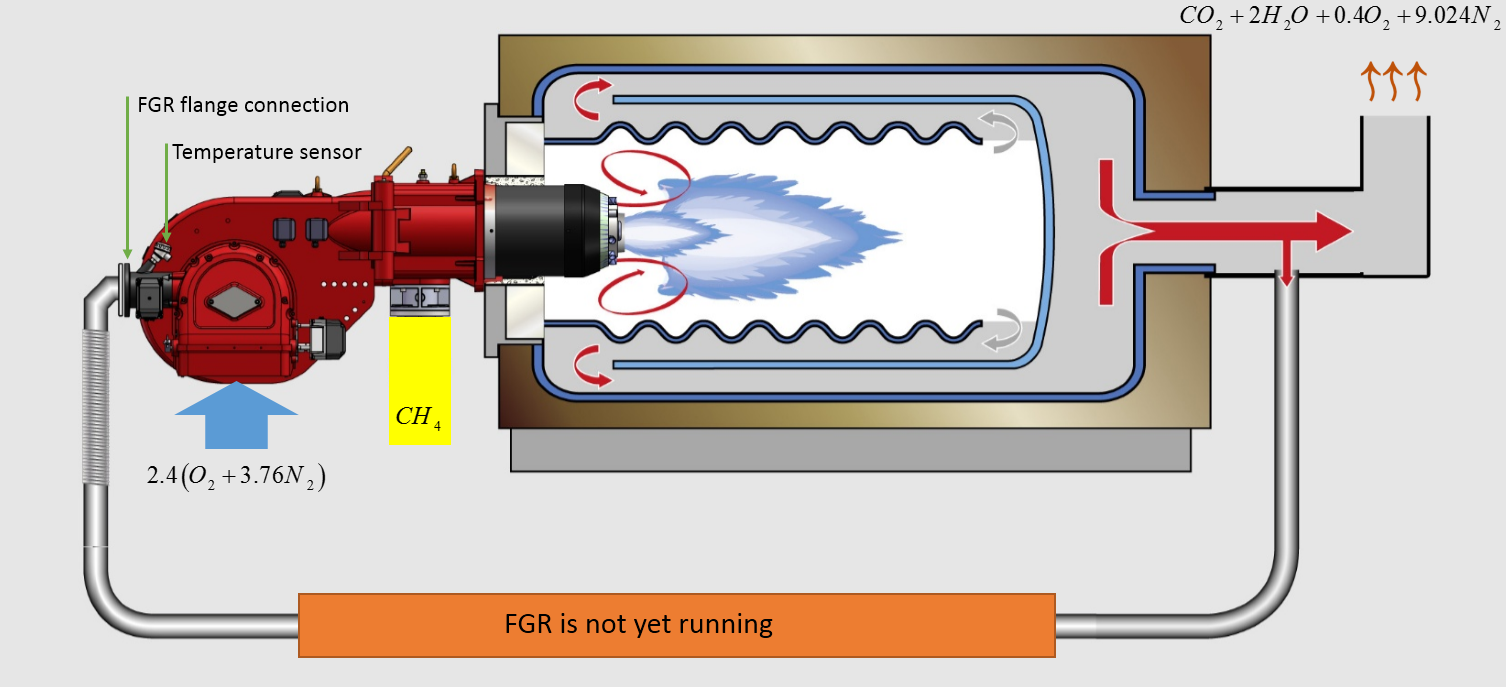

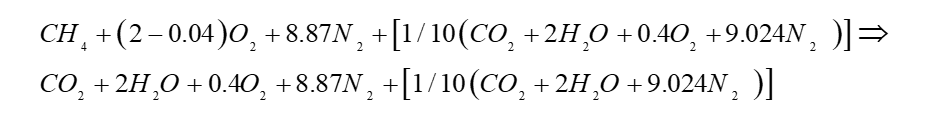

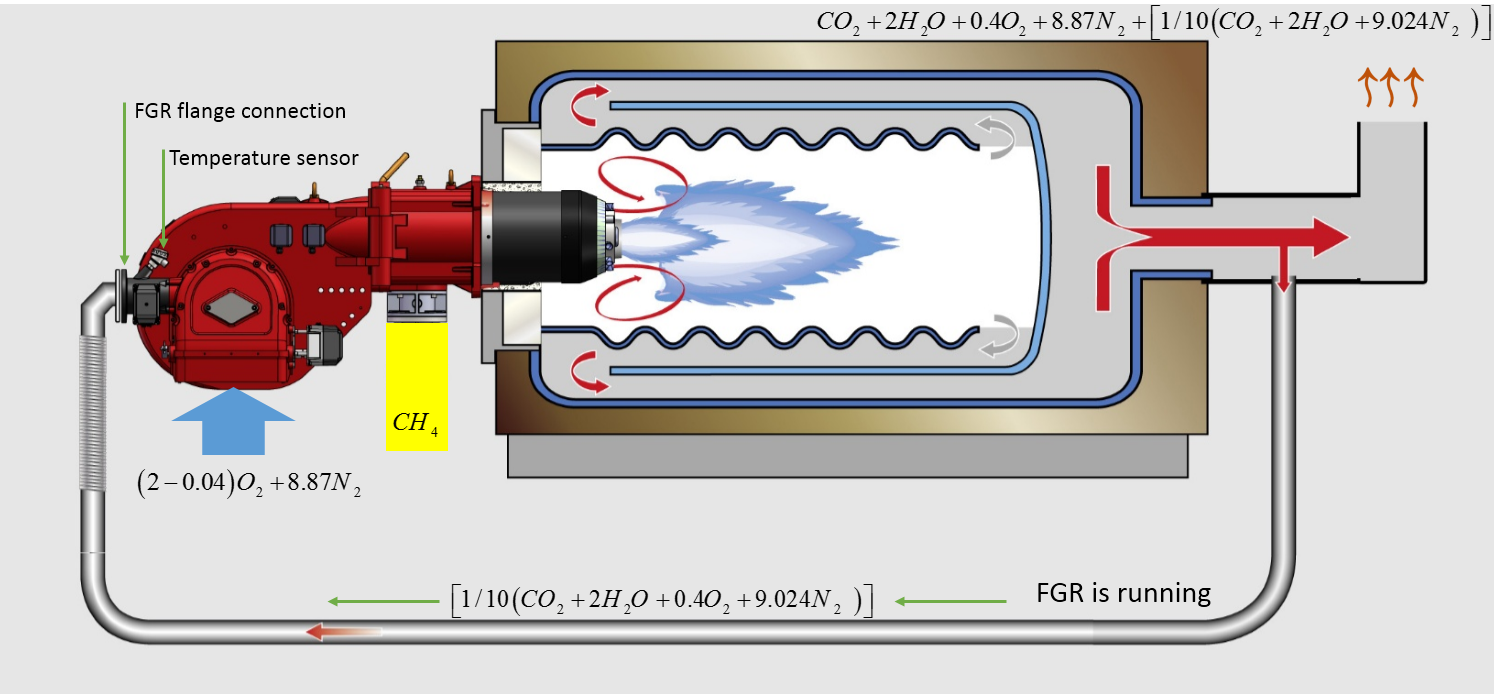

Figure 4- combustion of Methane at 20% excess air without FGR system

The recirculation system is shown in Figure 4 schematically. At the beginning, the combustion products recirculation is not active. The equation of methane combustion at 20% excess air is indicated in Equation 1. As it can be seen, the total number of moles resulting from combustion which absorb the combustion energy, equal 12/424 mole for burning one mole of methane. This causes a temperature in the range of 1300 degrees Celsius. This temperature is the main cause of forming thermal NOx.

Equation 1

If recirculation is 10%, in fact 10% of the combustion products, which mainly include neutral moles, will be transferred to the burner inlet. This transfer is done by pipeline connecting from the boiler chimney to the FGR inlet on the burner. The transmission path needs to be completely insulated thermally so that condensation not occur along it. The burner inlet also needs a discharge port for the possible condensation of water vapor combustion. The transmission is done by the burner’s fan in small capacities. Separated fans which are function of central control system, are used in large capacities to push the combustion products toward the burner. The combustion products contain some oxygen, too. Therefore, by transferring a percentage of combustion products, the inlet air to the burner is reduced so that the combustion operation is fully observed at 20% excess air. In this case, the reaction equation will be changed and the moles resulting from combustion equal to 13/47 mole for burning one mole of methane. This mole increase means the particles in the combustion chamber of the boiler are increased. The energy in the combustion chamber has not changed since the mole of Methane is constant. This means that the previous cycle heat (without FGR system) is distributed 13/47 instead of 12/424 which means a 7-8 % decrease in flame temperature. This can be repeated in the following cycles in the same way and the system reaches balance after passing some cycles in short time. Reducing the flame temperature strongly reduces the thermal NOx. The combustion equation in the initial cycle of FGR running is indicated in Equation 2 and the process is shown schematically in Figure 5.

Figure 5- combustion of Methane at 20% excess air and 10% flue gas recirculation

Equation 2

The applicable percent for recirculation depends on burner type and its head mixing power.

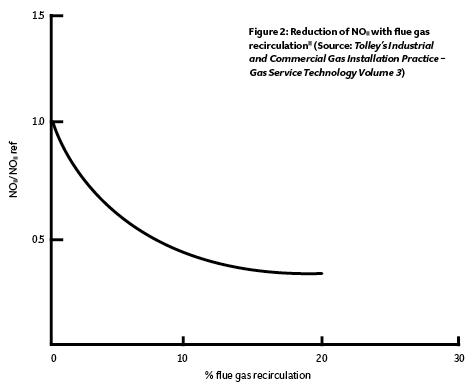

The diagram in Figure 6 shows the NOx reduction in terms of recirculation percentage. As it can be observed, this method can reduce NOx by 50%. Generally, it is recommended to do the experiment to 20% for the burner manufacturers.

If the recirculation with the aim of NOx reduction exceeds this value, the burner flame becomes very voluminous and causes negative effects on heat transfer levels in the boiler combustion chamber. In this case, the user has to reduce the capacity.

Figure 6- NOx reduction in terms of recirculation percentage

If the boiler has two or more burners, each burner will have separate FGR port. The management system adjusts the recirculation amount of each separately with the aim of reducing the flame’s general NOx. Recirculation has insignificant negative effects on efficiency since the flame temperature is lower and this will decrease thermal capacity a little. The general solution to compensate this reduction is to increase the mixing in the heat transfer paths. Another negative effect is the actual price of the burner. Setting up the FGR system will cost about 20% of total actual price of the burner. This cost includes piping, sensor, modular motor connected to the burner port and etc.

This cost will be more for one per kw fuel consumption in low capacity. According to the report by the US Environmental Protection Agency, among all NOx reduction methods, FGR is the most economical method for burners with capacity of over 500 kW.

All the operations described in this report, which are in sync with the researchers in the field of facilities in American and European Unions, are set up in Packman and are practically applicable for the burners with capacity of over 1700kw. Figure 7 shows an example of FGR application on two burners with capacities of 10Mw and 5Mw.

It is hoped that a strong and effective step can be taken to preserve the environmental health and protect it for the future generation by reducing NOx from heating and steam systems by 50% which include 35% of the country’s pollution.

Figure 7- recirculation port of combustion products on RLGB-M/M-505/LN and RLGB-M/M-1050/LN burners by Packman Company

In conclusion, the Flue Gas Recirculation has a significant effect in reducing NOx emission. As it can be observed in the provided figures and diagrams, this system can reduce NOx by up to 50%. It should be noted that the applicable percent for recirculation depends on the burner type and mixing power of head. According to industry recommendation, conducting the experiments to 20% is advisable to the manufacturers since exceeding this value will cause negative effects. Therefore, it is crucial to strike a balance between NOx reduction and burner capacity to have a sustainable boiler operation. More scientific research is needed in this field to inform the manufacturers on how to improve efficiency and protect the planet.

Authors: The Research Department of Burner Factory, Packman Company, Managed by Vahid Azizi

Reference:

Related Article

Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and the need

During the last century, Nitrogen oxide emissions, called NOx, have constantly been increasing. Due to the destructive effects of nitrogen oxides on the health of society and

The «furnace industry» and products determine the type of flame contact. In many heat treatment processes, where the combustion gases must not come into contact with the

PACKMAN Company was established in February, 1975. The company has started its activity in the field of producing High-Pressure Vessels such as Hot-Water Boilers, Steam Boilers, Pool Coil Tanks, Softeners and Heat Exchangers since 1984.

Newsletter