Overview of Petro-refinery burners and Their Use in Industrial Furnaces

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Boilers serve as fundamental components in heating systems, supplying the thermal energy essential for a range of industrial and commercial applications. The burner, as the

In today’s world, energy conservation reducing environmental pollution are top priorities across various industrial sectors. Burners, as the central components of industrial furnaces and boilers,

RGB-M Series or RAADMAN Electrical Modular Monoblock gas burners, covering a firing range from 160 to 17000 kW, are designed for a wide range of domestic and industrial applications. All RAADMAN modular burners are equipped with LAMTEC or SIEMENS electronic control system with capability of full air/gas ratio control throughout entire burner operating range. These burners have been tested and evaluated based on Iran national standard ISIRI-7595 (BS-EN 676). According to performed experiments, the values of CO even in low excess air operation is lower than 30 mg/kWh (In some cases, values close to zero have also been reported). The precise design of combustion head results a full gas-air mixture that guarantees high efficiency levels in all various applications. Burner superior design accompanied by high quality electronic devices have also resulted a further improvement in boiler’s performance in order to decrease the fuel cost and emissions.

|

|

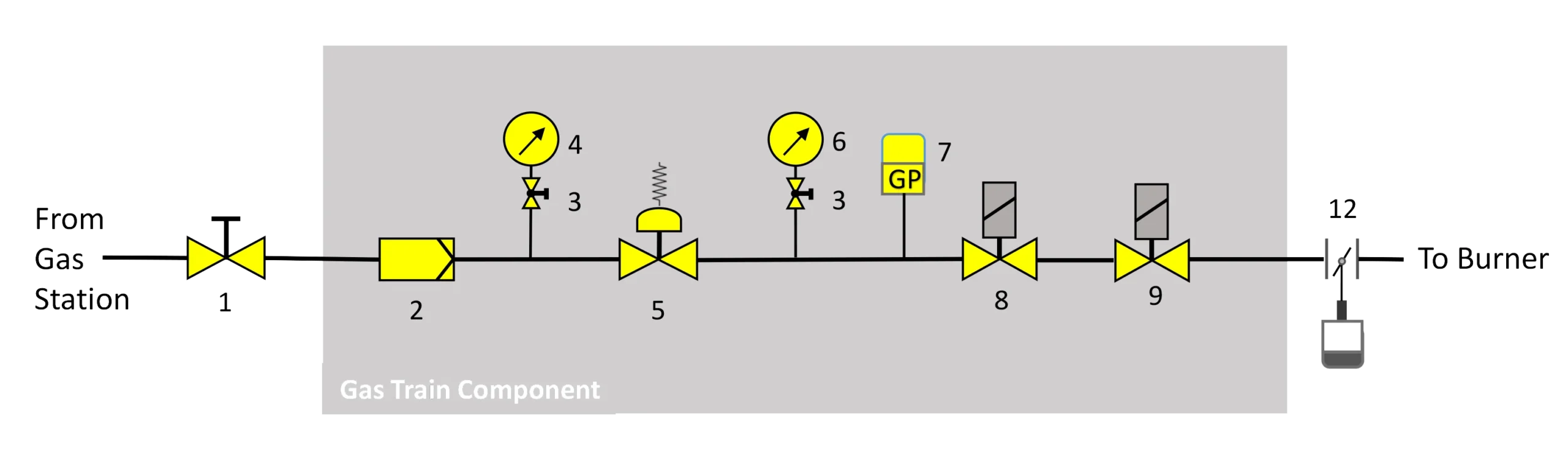

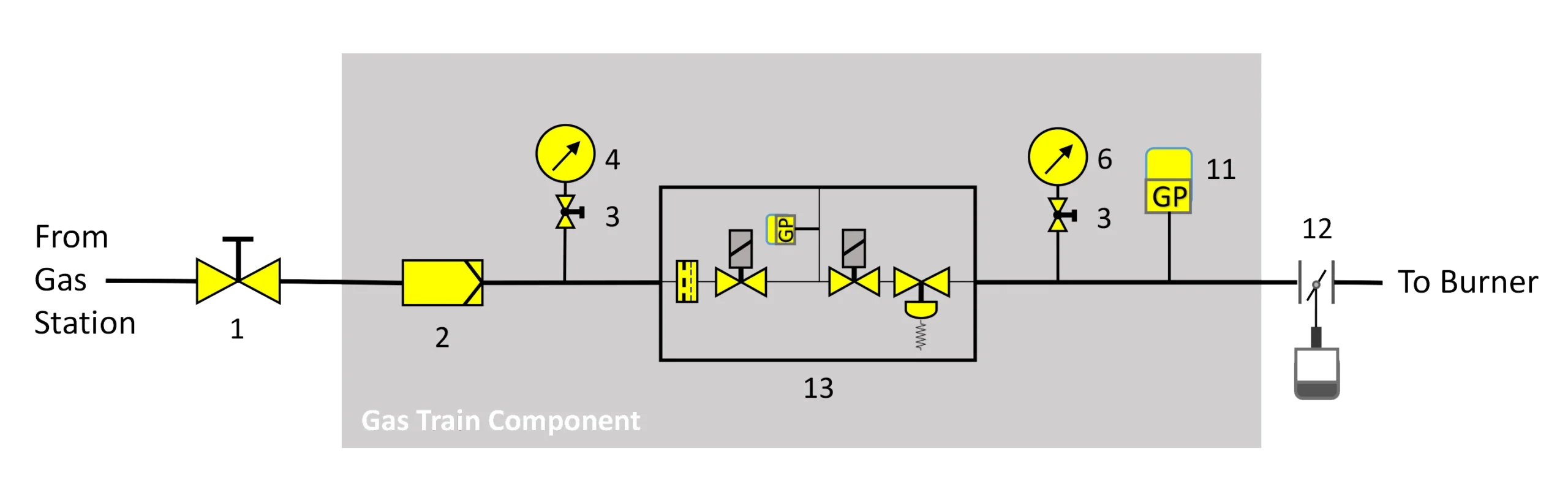

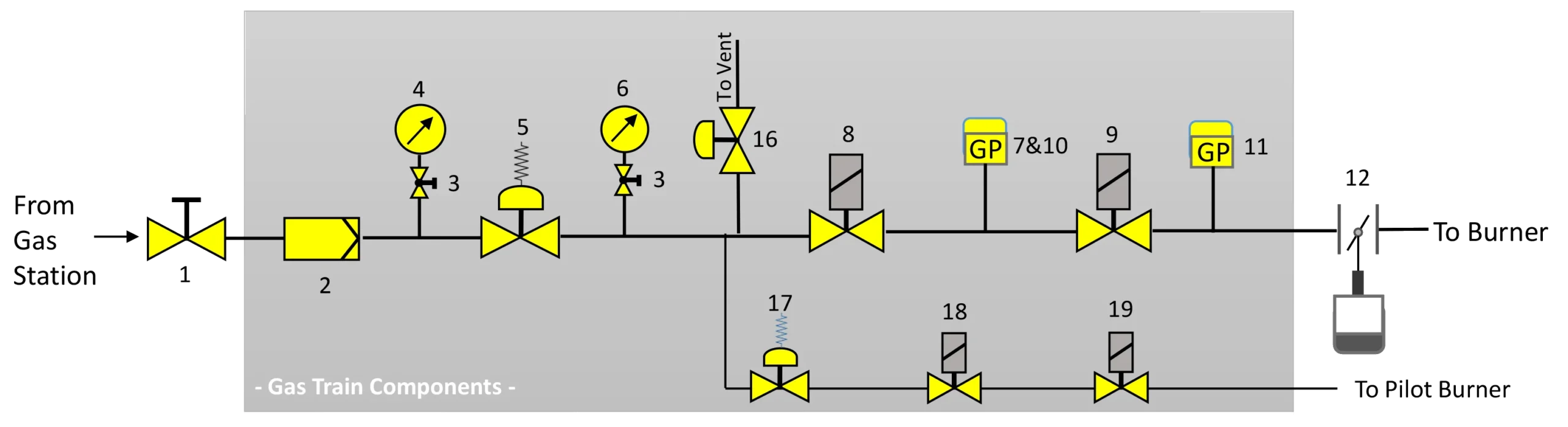

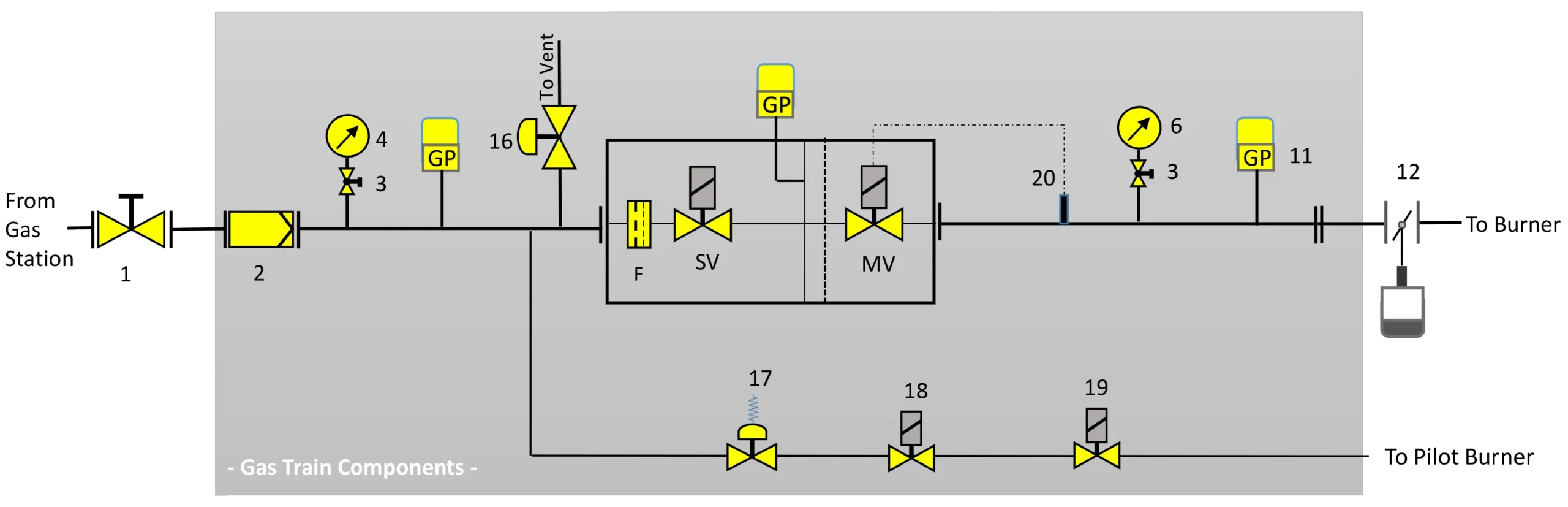

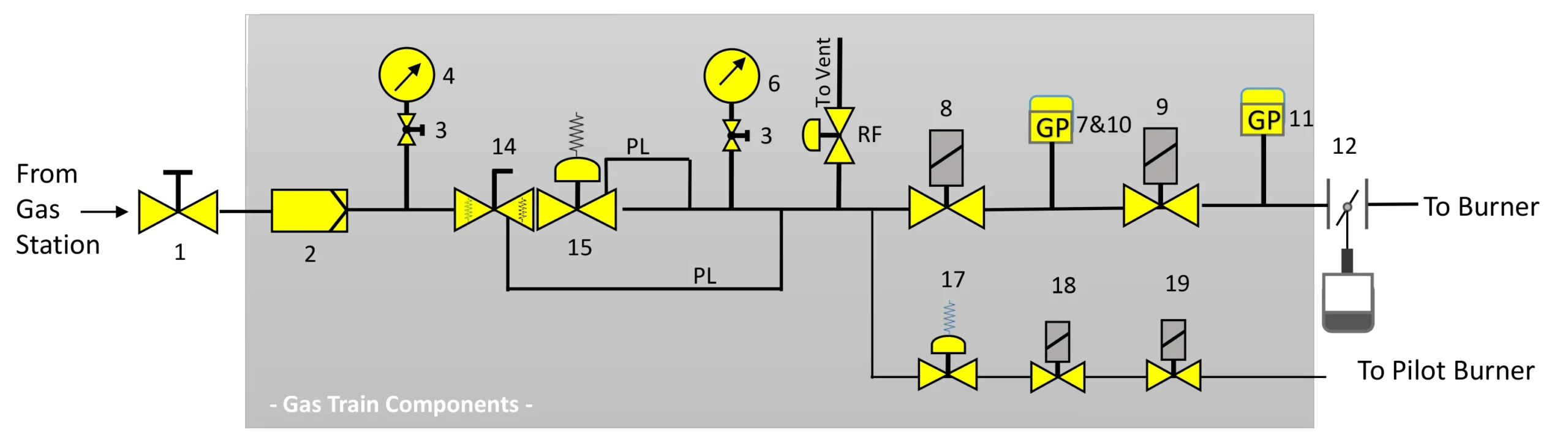

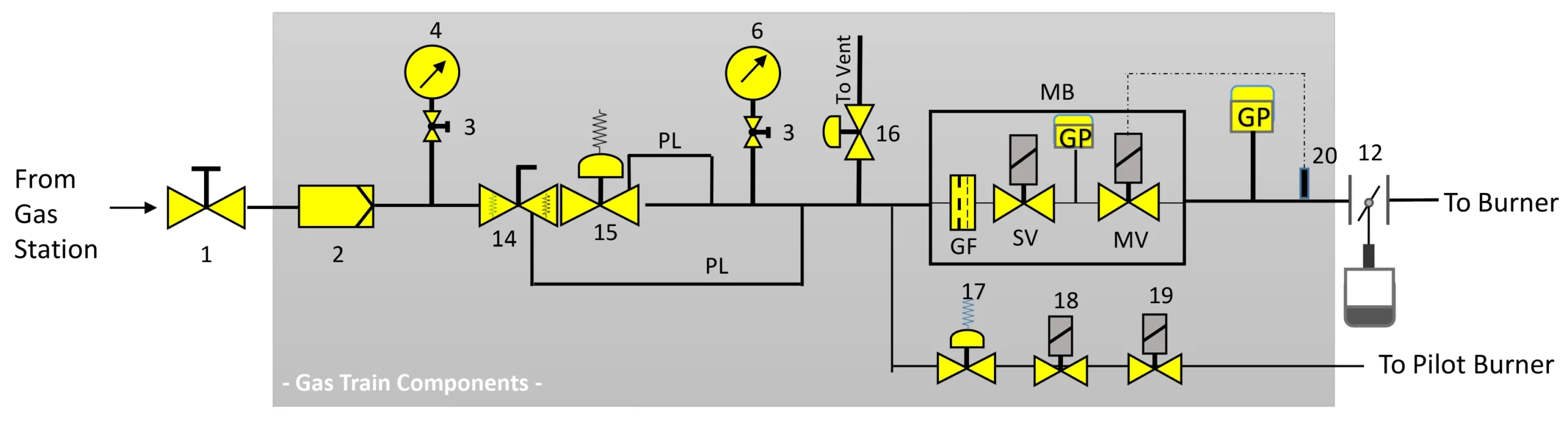

| 1: Ball valve | 8: Safety gas valve | 14: Shut-off valve |

| 2: Gas filter | 9: Main gas valve | 15: High pressure regulator |

| 3: Push button valve | 10: Leak Test gas pressure switch | 16: Relief valve |

| 4: Pressure Gauge | 11: Max gas pressure switch | 17: Pilot regulator |

| 5: Pressure regulator (Low-pressure) | 12: Butterfly valve | 18: Pilot valve 1 |

| 6: Pressure Gauge | 13: Multi-Block Solenoid Valve | 19: Pilot valve 2 |

| 7: Min gas pressure switch |

Newsletter