Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

During the last century, Nitrogen oxide emissions, called NOx, have constantly been increasing. Due to the destructive effects of nitrogen oxides on the health of

The «furnace industry» and products determine the type of flame contact. In many heat treatment processes, where the combustion gases must not come into contact

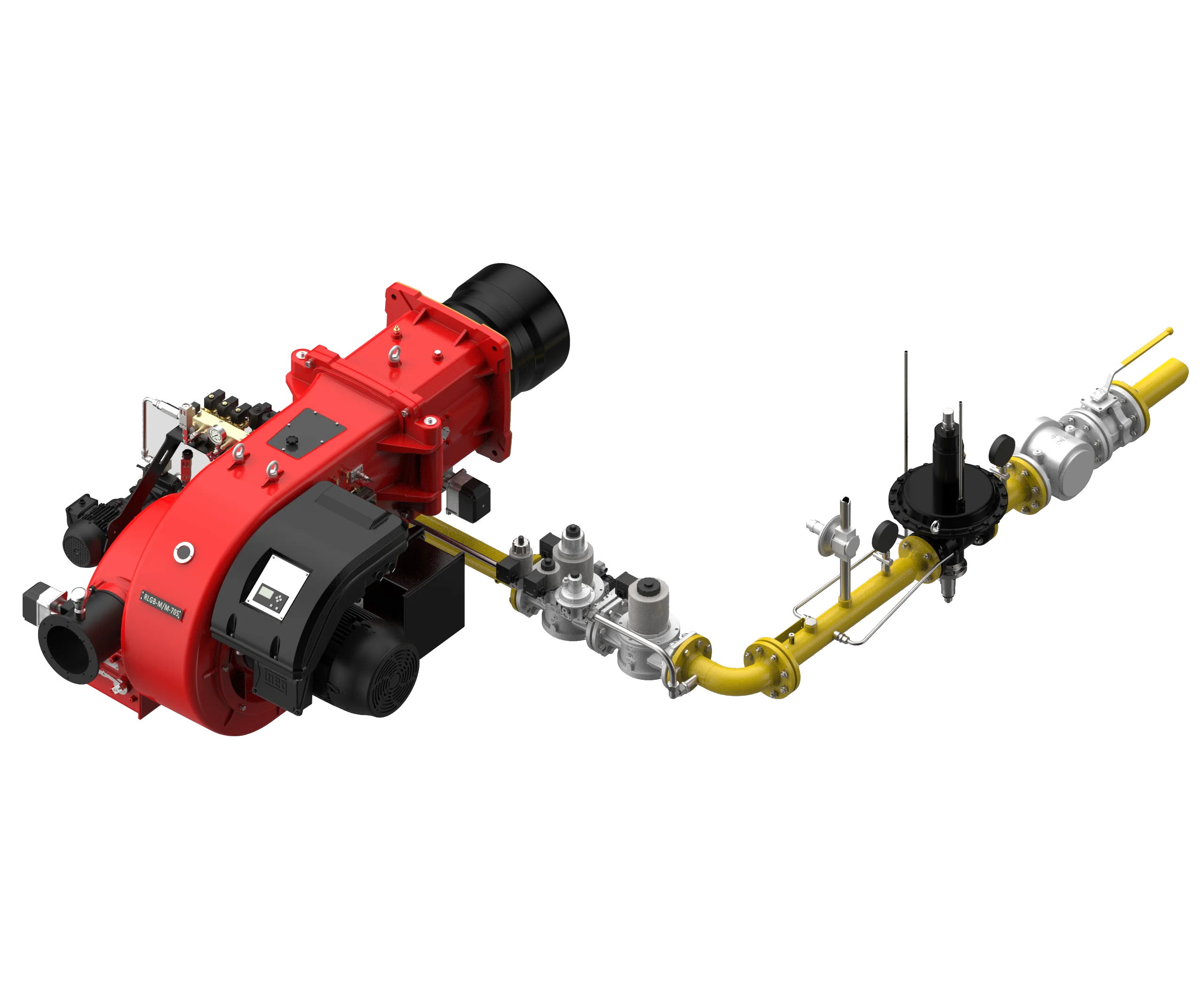

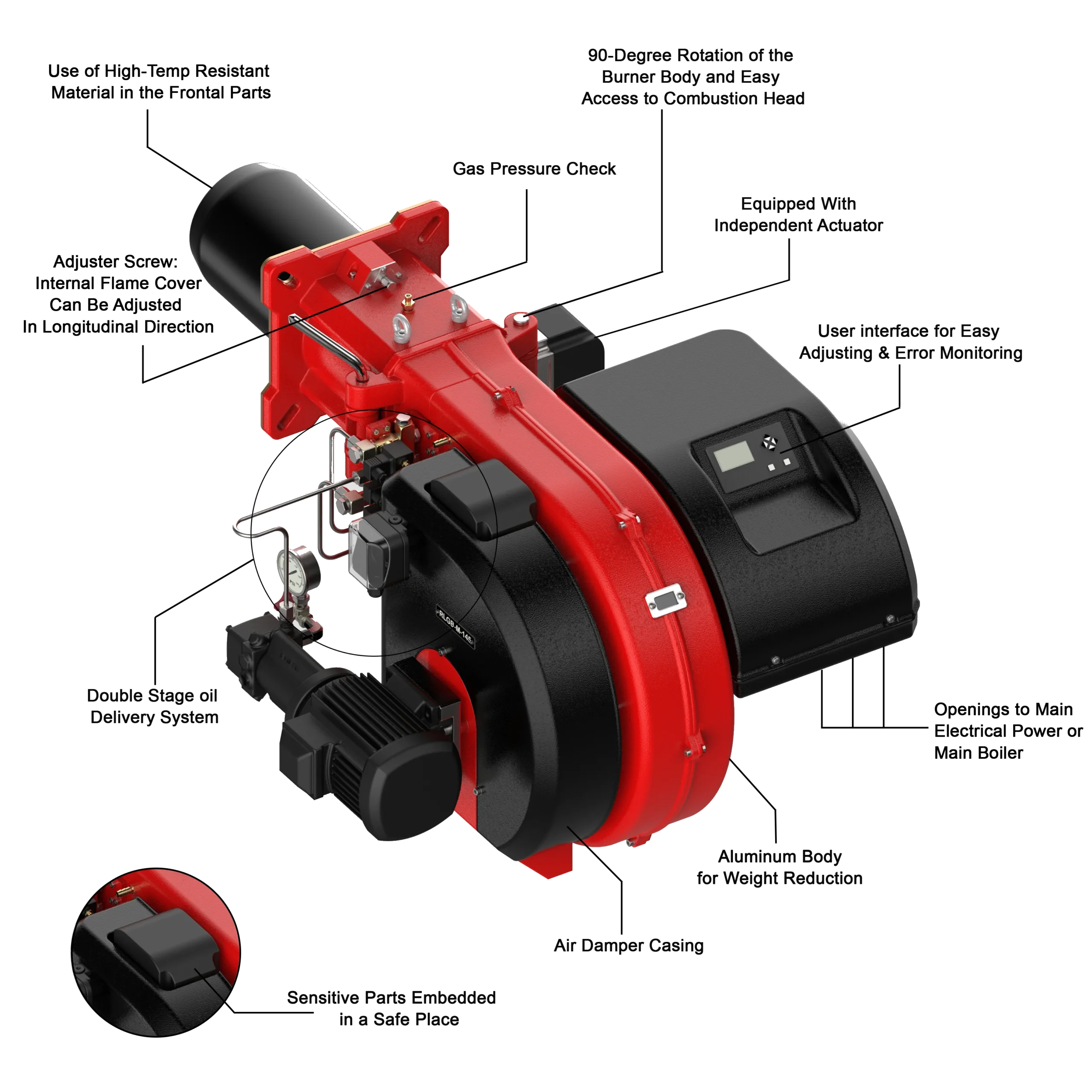

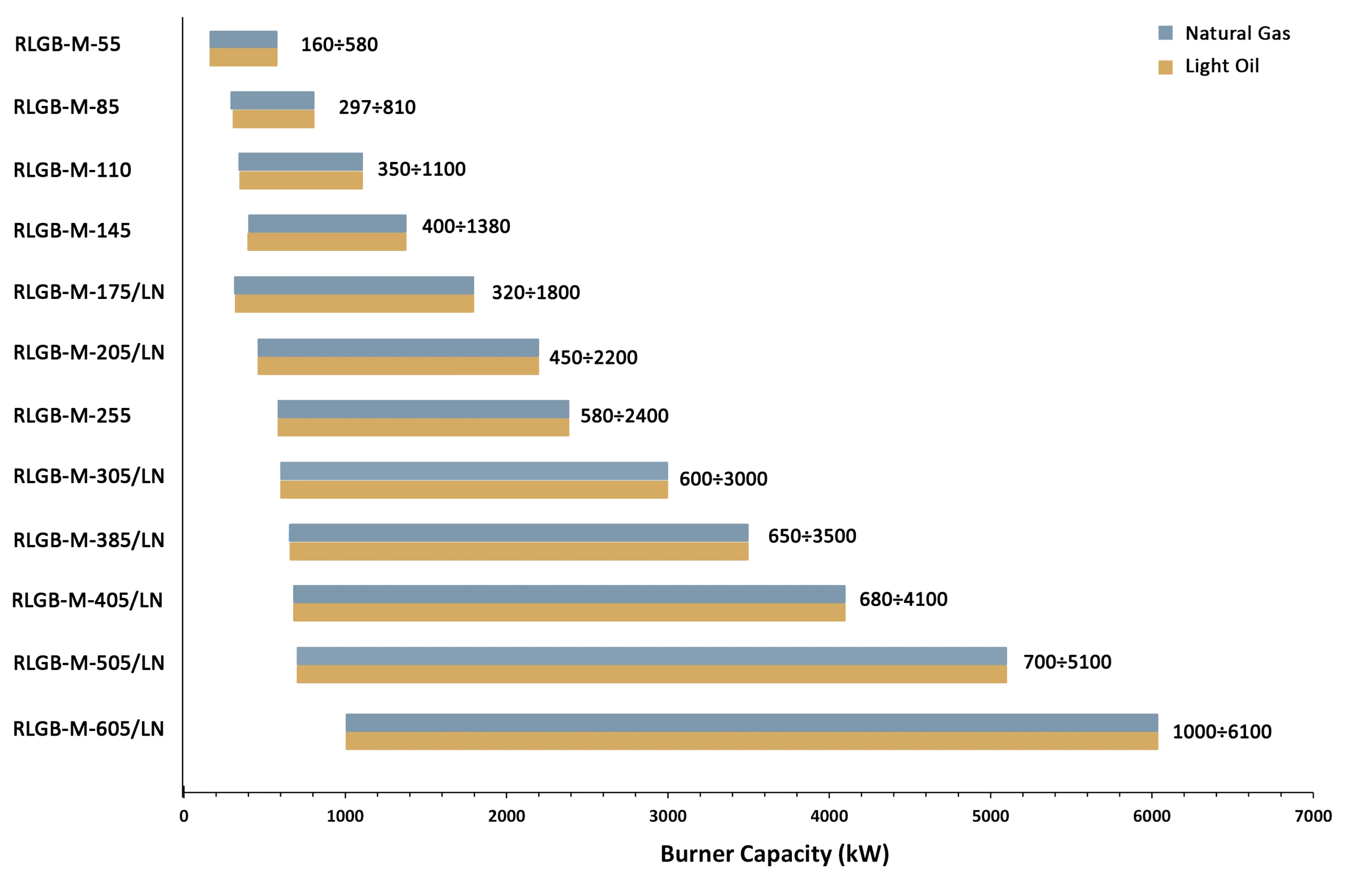

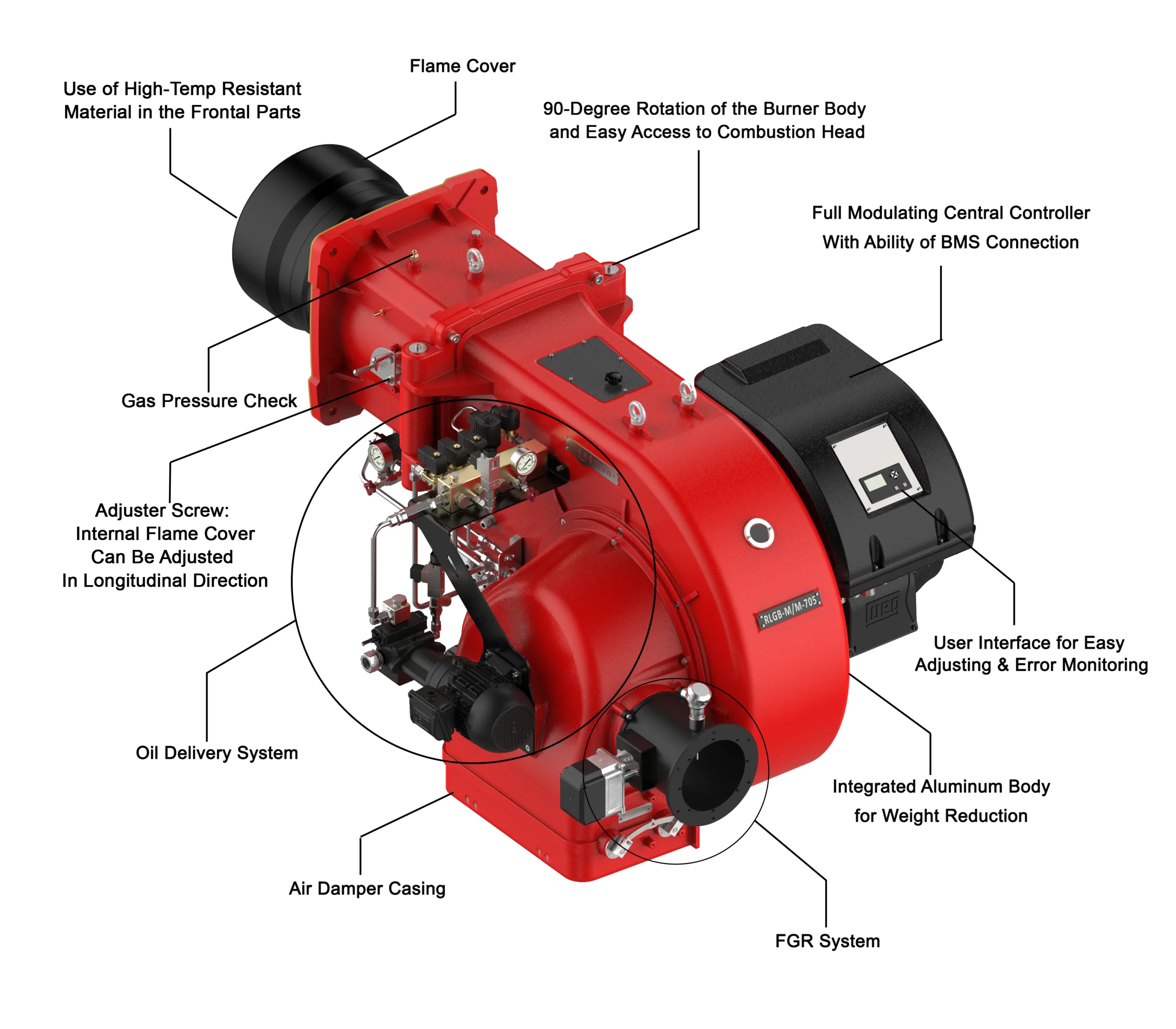

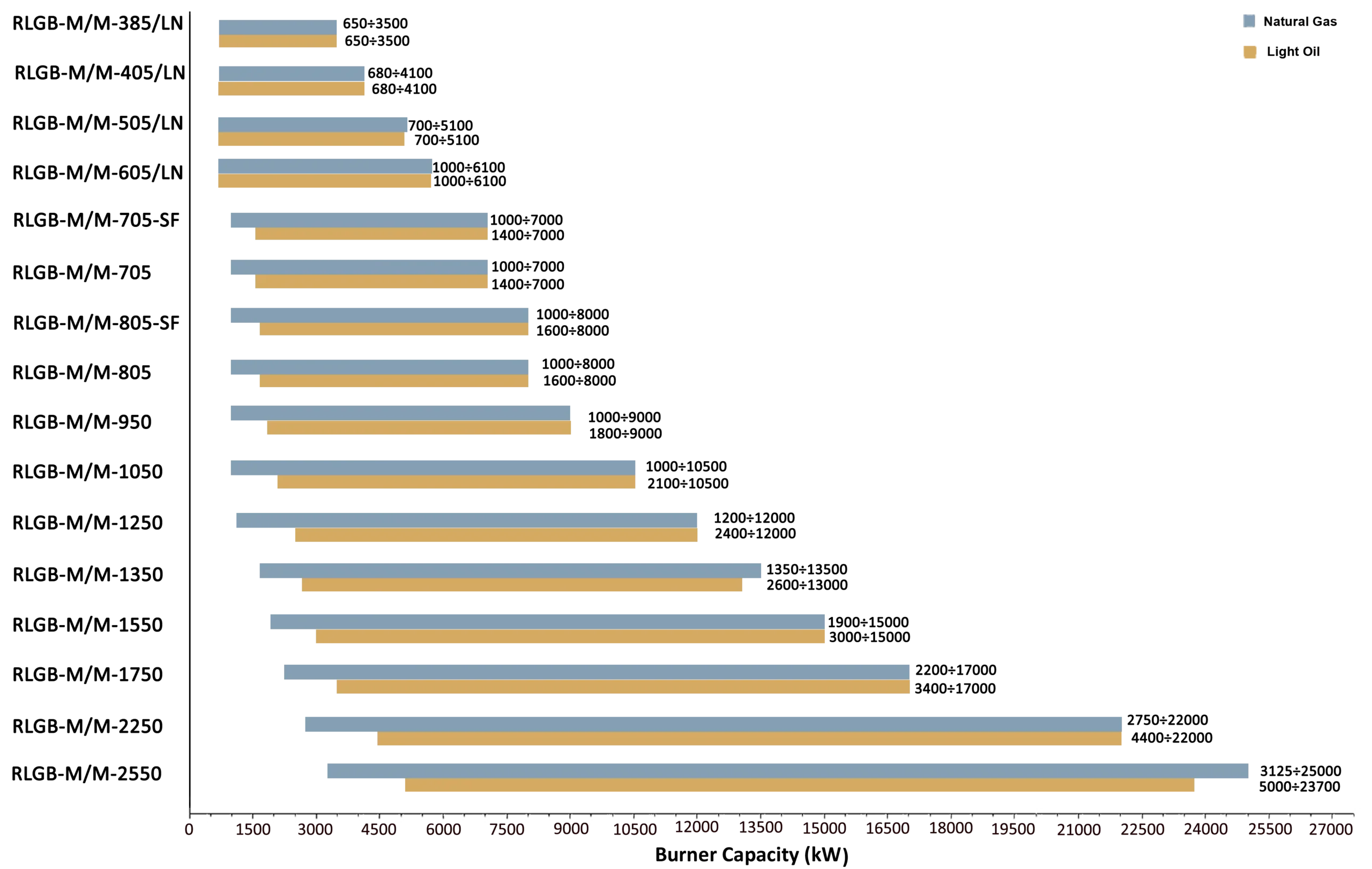

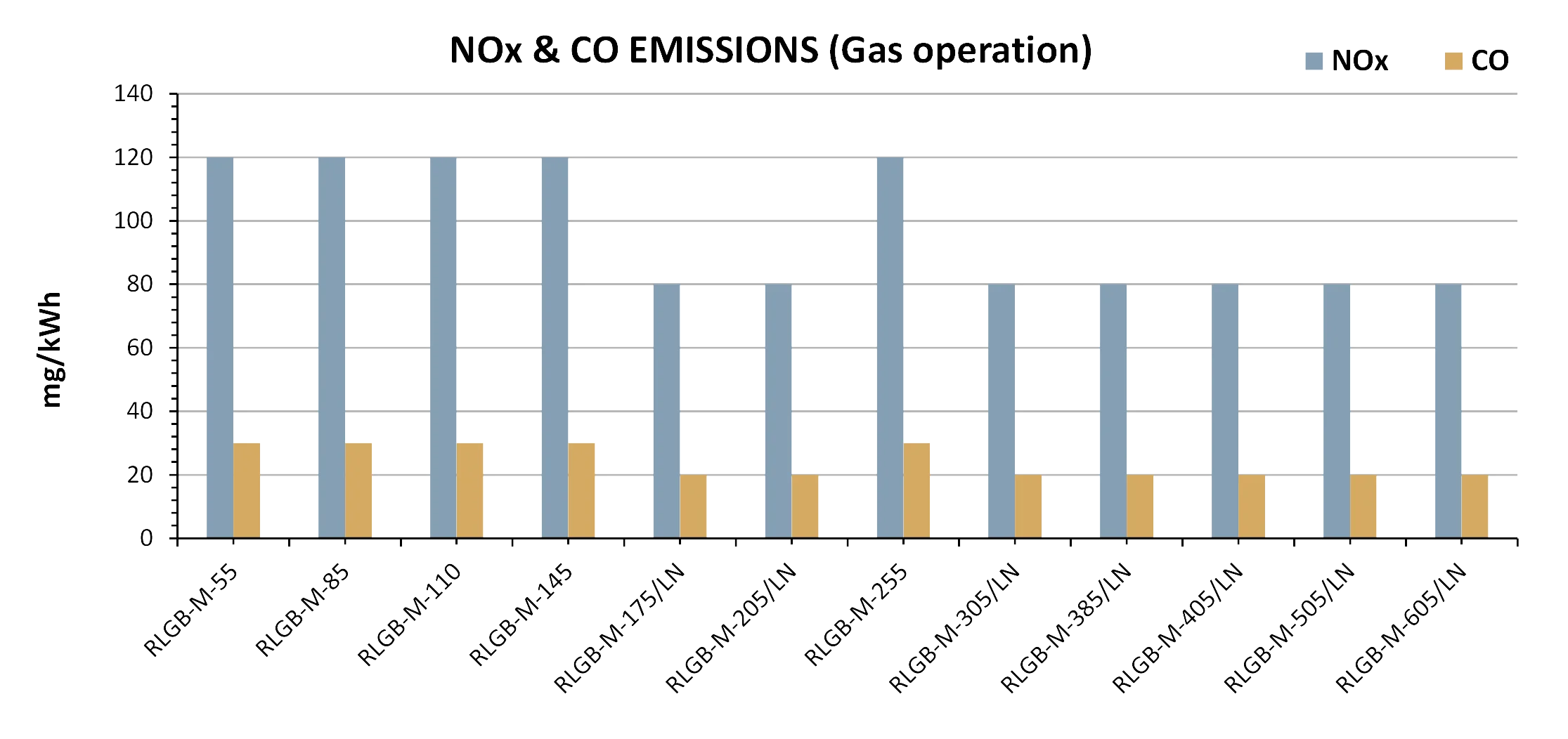

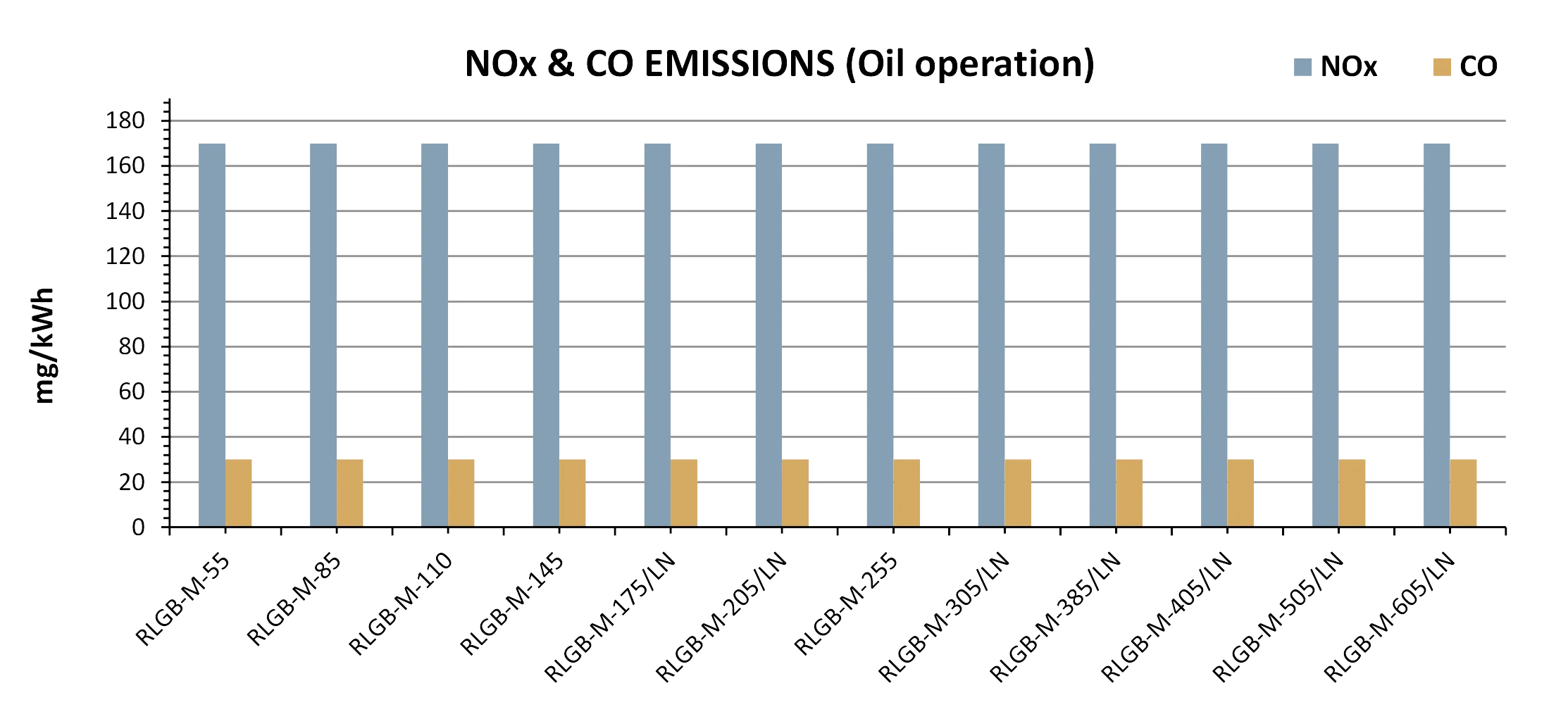

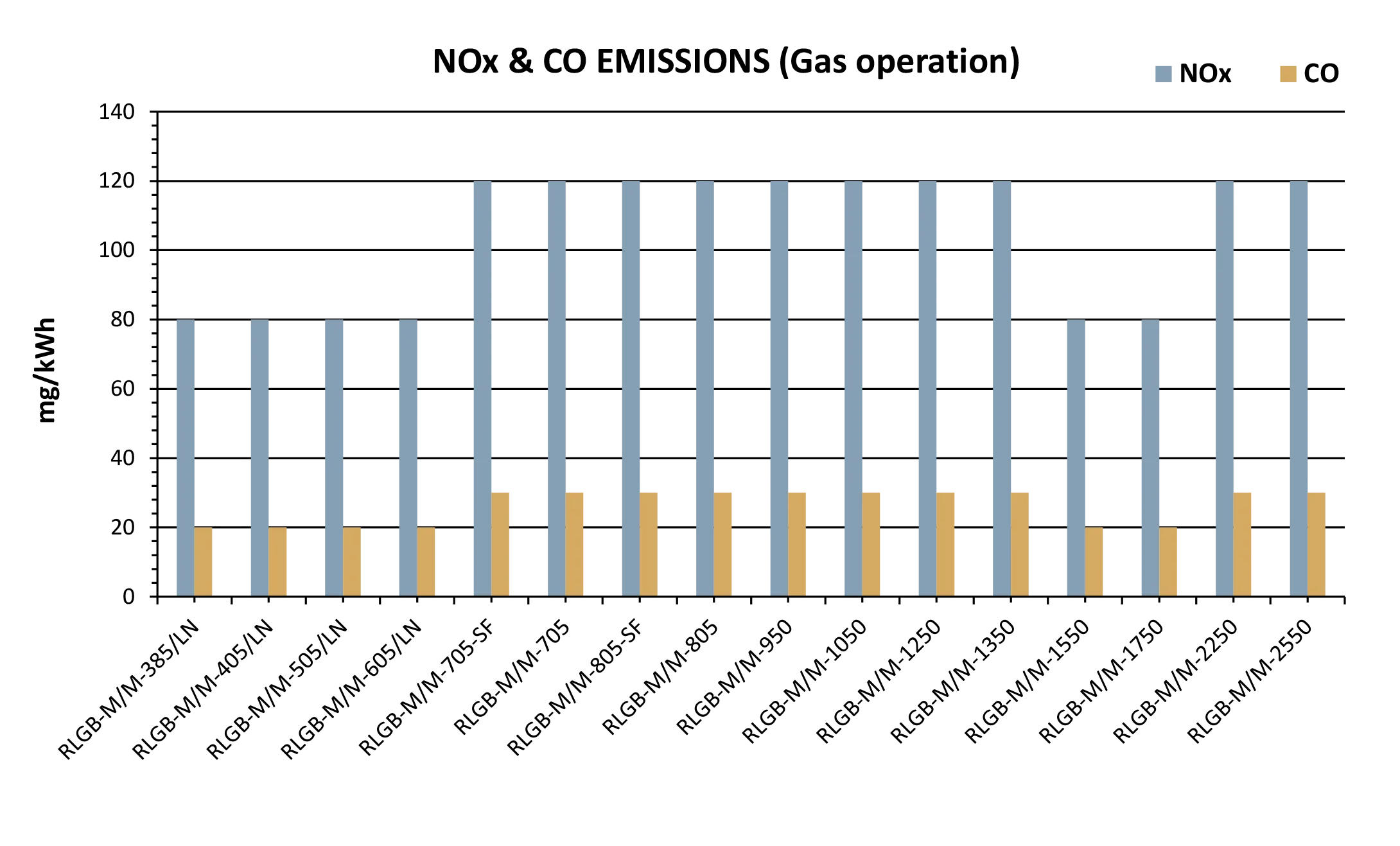

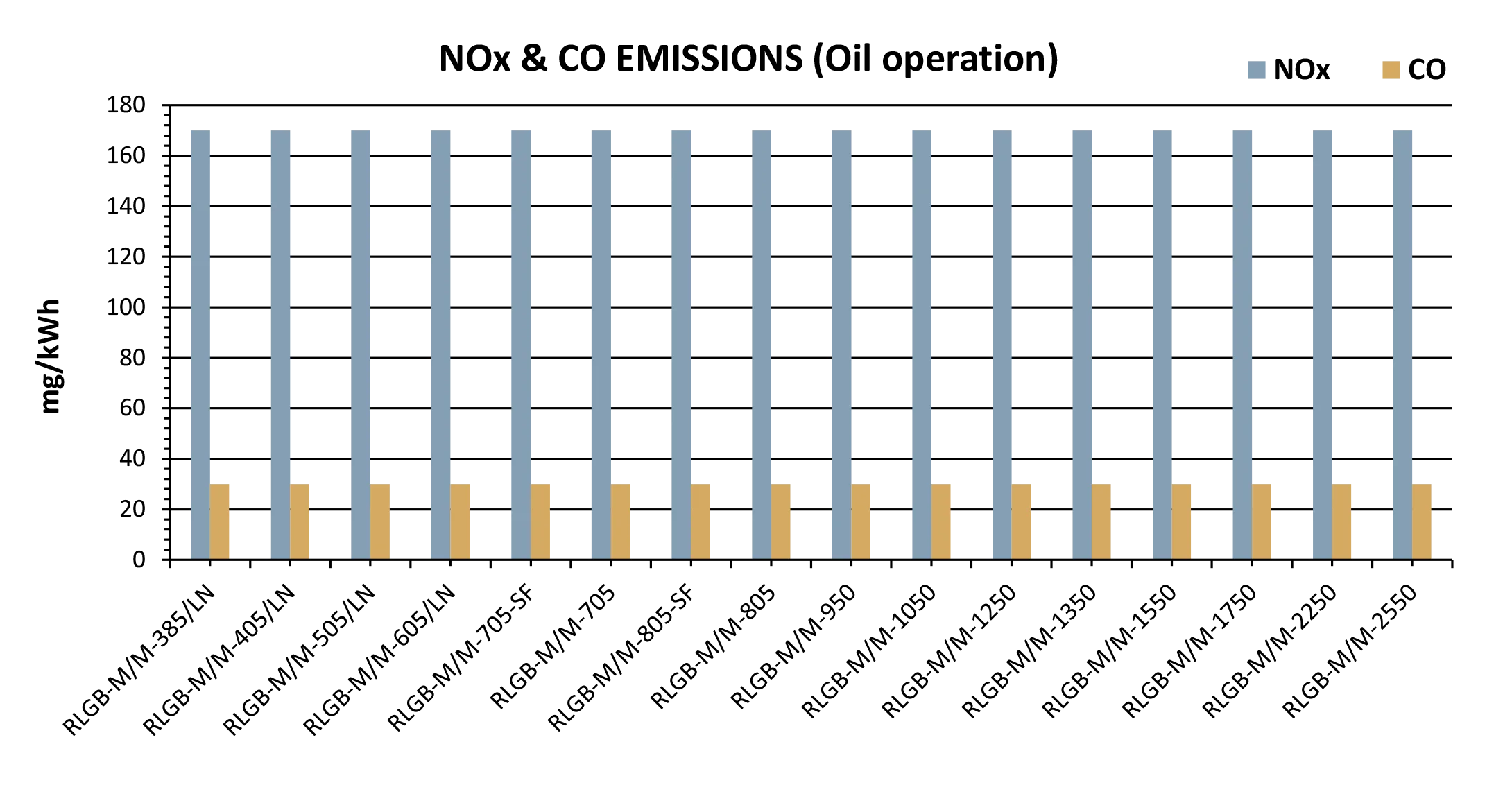

RLGB-M Series or RAADMAN Modulating dual fuel burners, covering a firing range from 700 to 17000 kW, are designed for a wide range of domestic and industrial applications. These Industrial burners have been tested and evaluated based on Iran national standard ISIRI-7595 (BS-EN 676) and ISIRI-7594 (BS-EN 267) for gas and oil operation respectively. According to performed experiments, the values of CO during low excess air operation is lower than 30 mg/kWh (in some cased very close to Zero). The precise design of their combustion head results a full gas-air mixture that guarantees high efficiency levels in all various applications. These Monoblock burners are equipped with LAMTEC and SIEMENS control system with capability of full air/gas ratio control throughout entire burner operating range as well as devices of well-known European companies such as Dungs, Kromschroder and Suntec. Burner superior design accompanied by high quality electronic devices have also resulted a further improvement in boiler’s performance in order to decrease fuel cost and emissions.

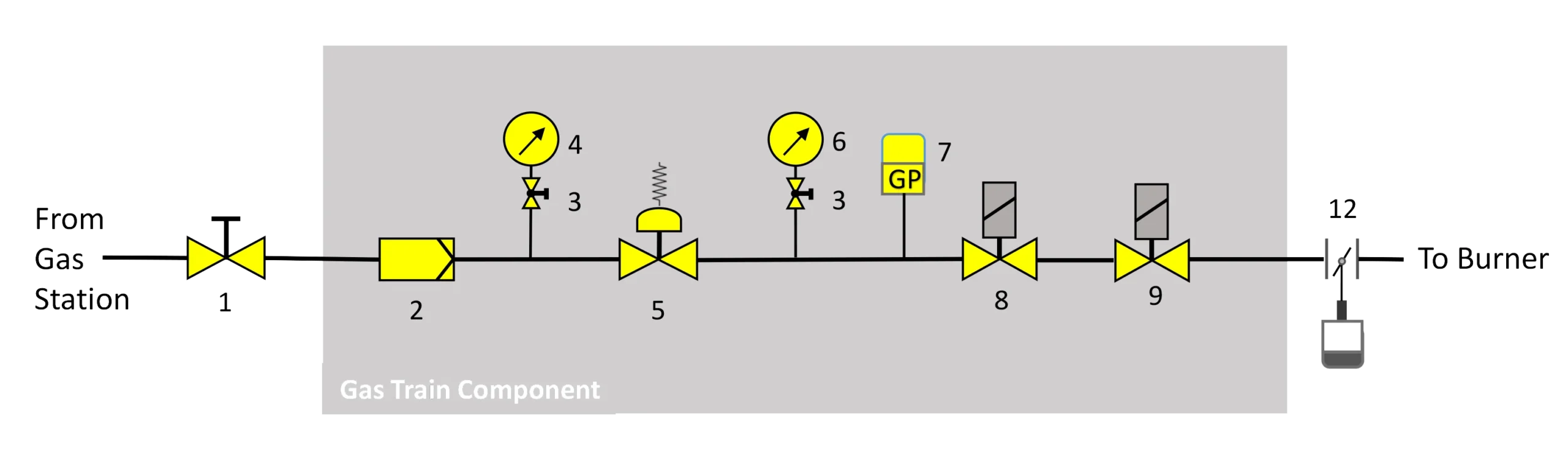

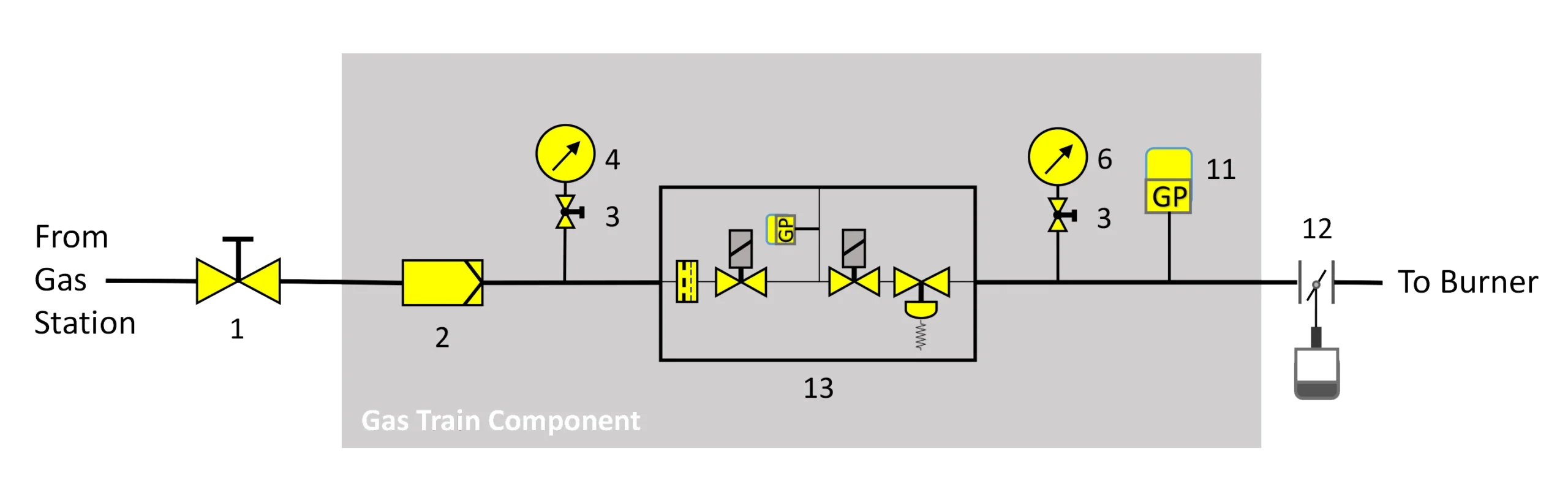

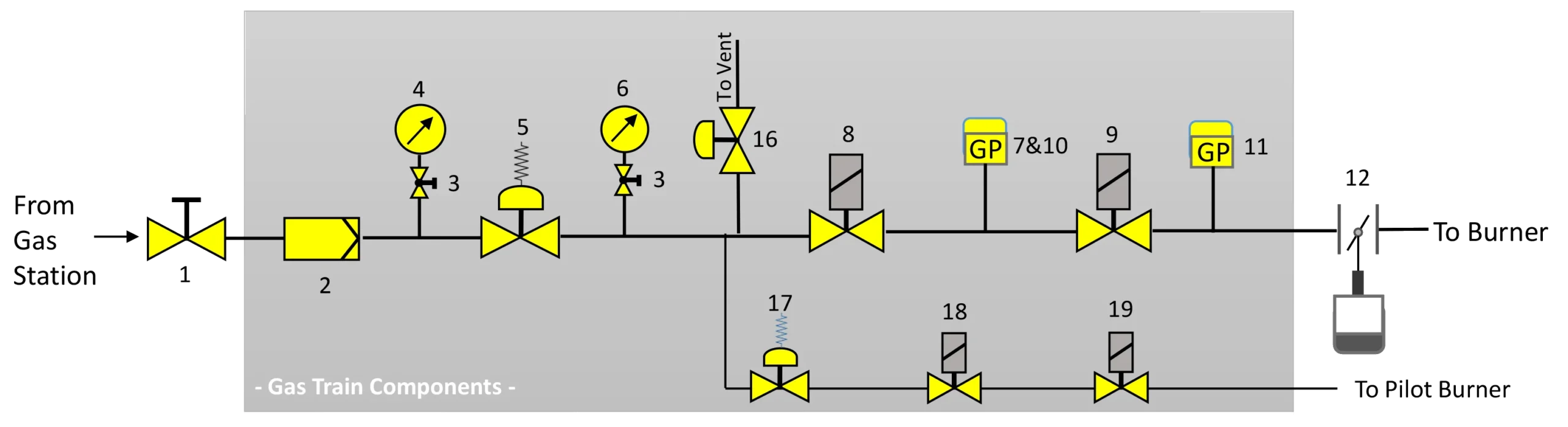

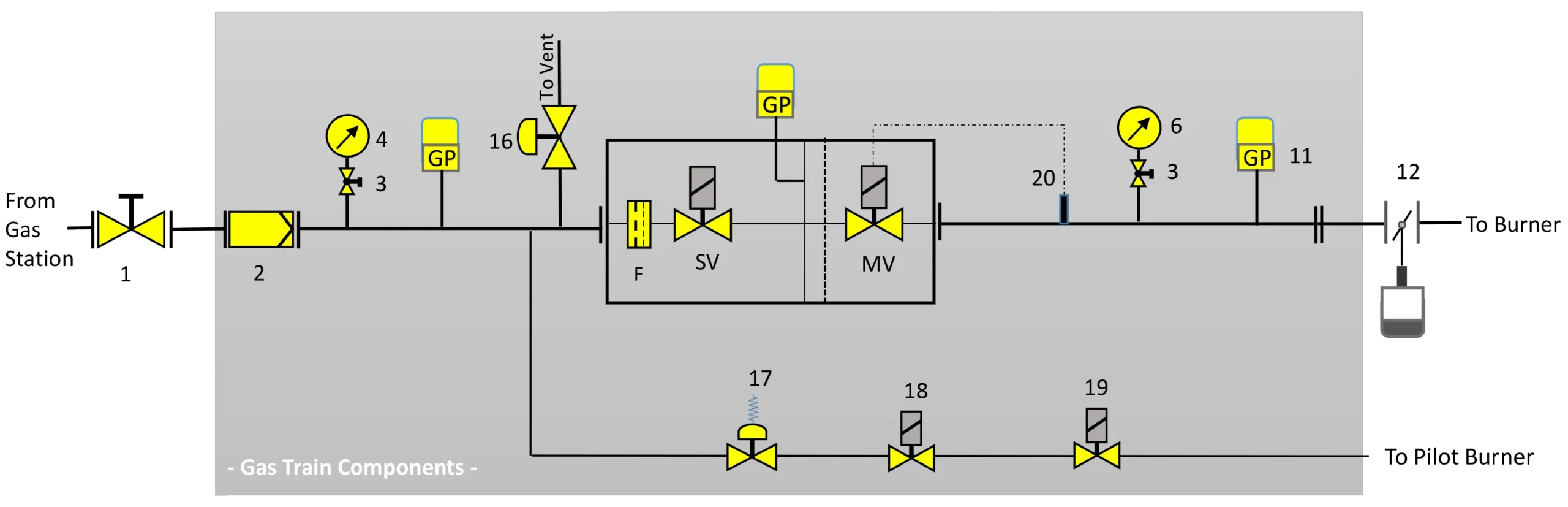

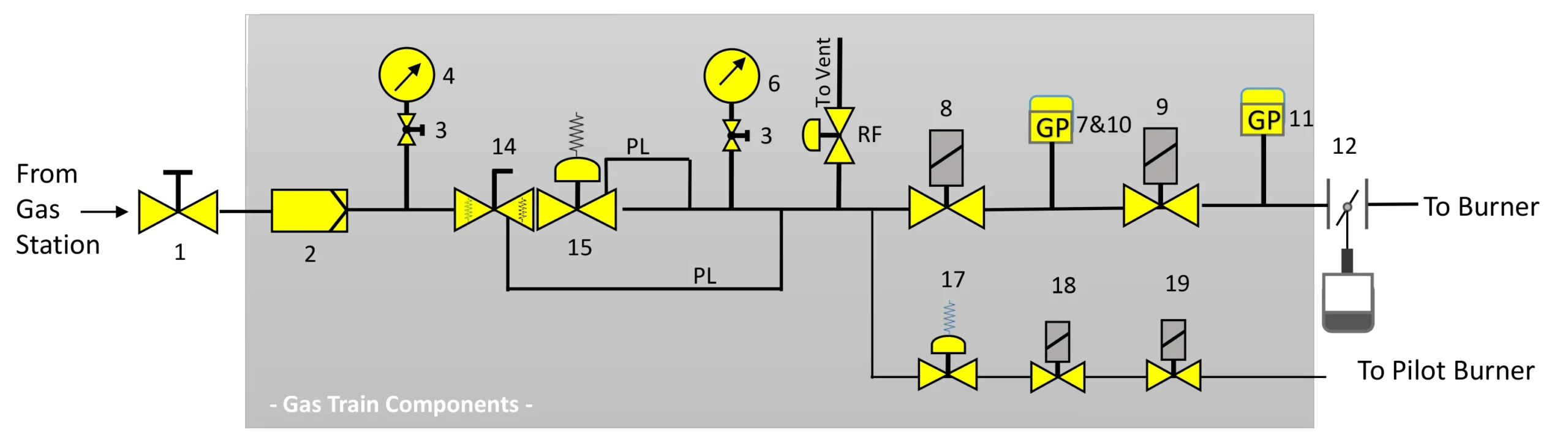

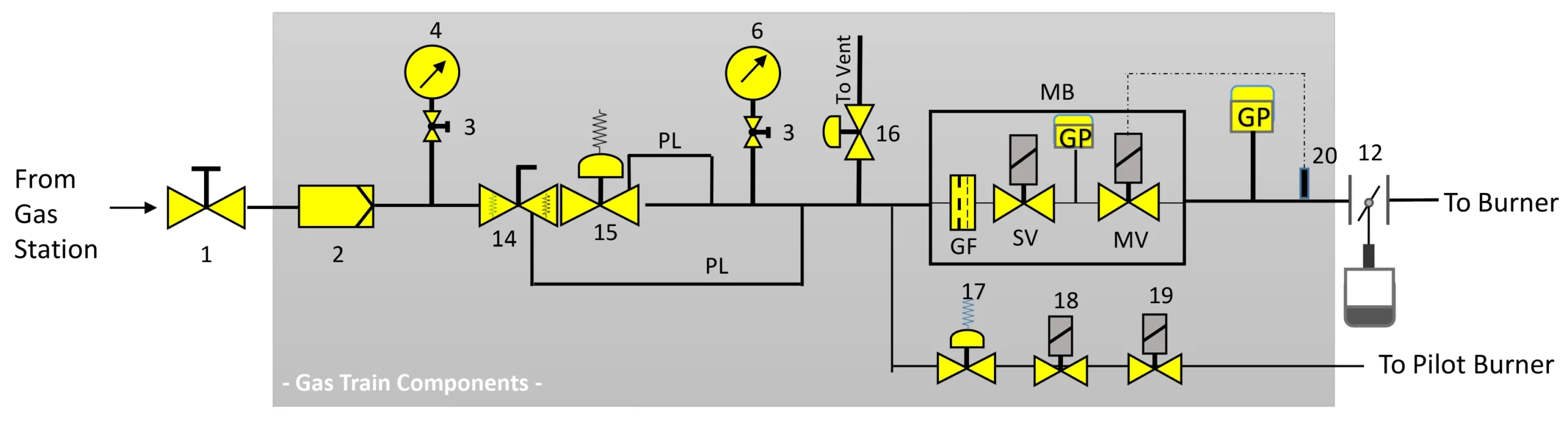

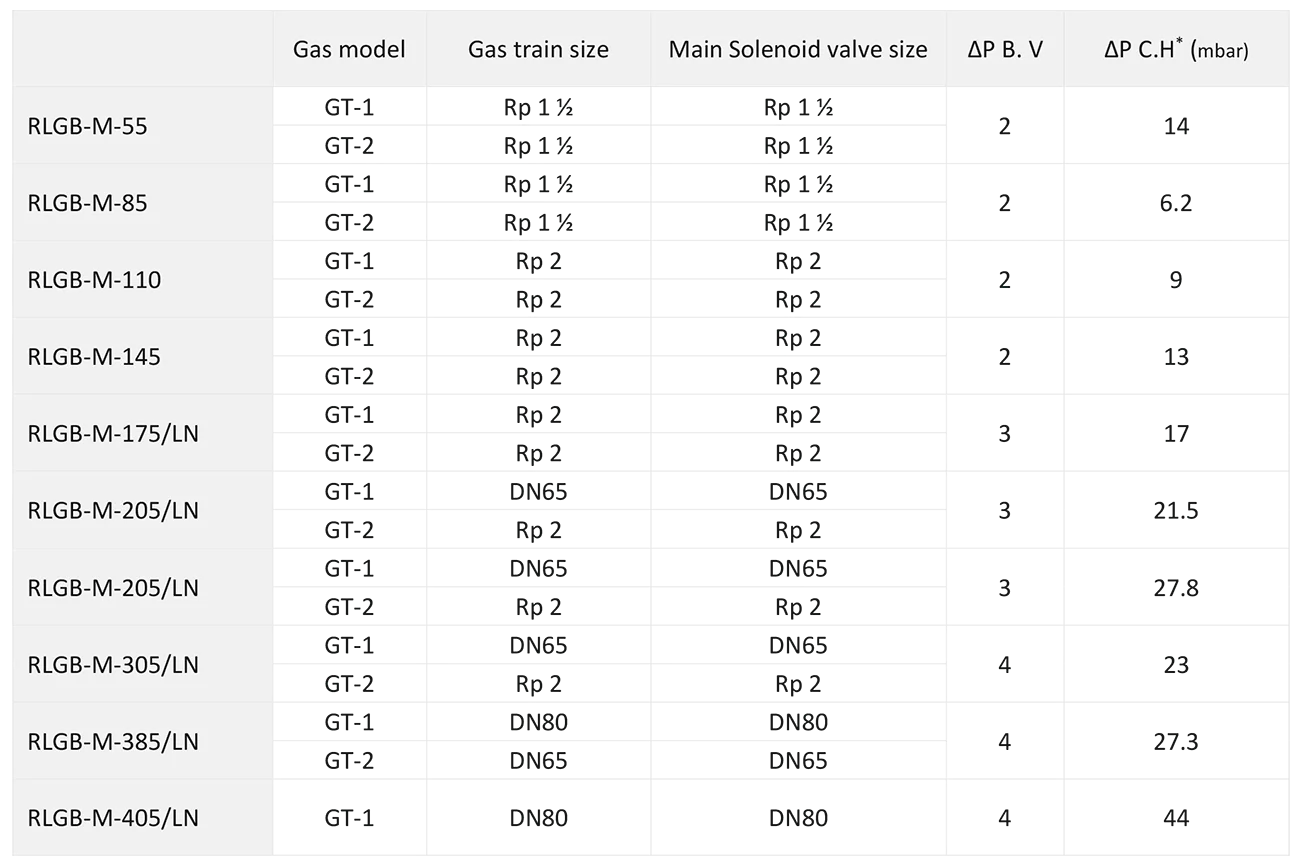

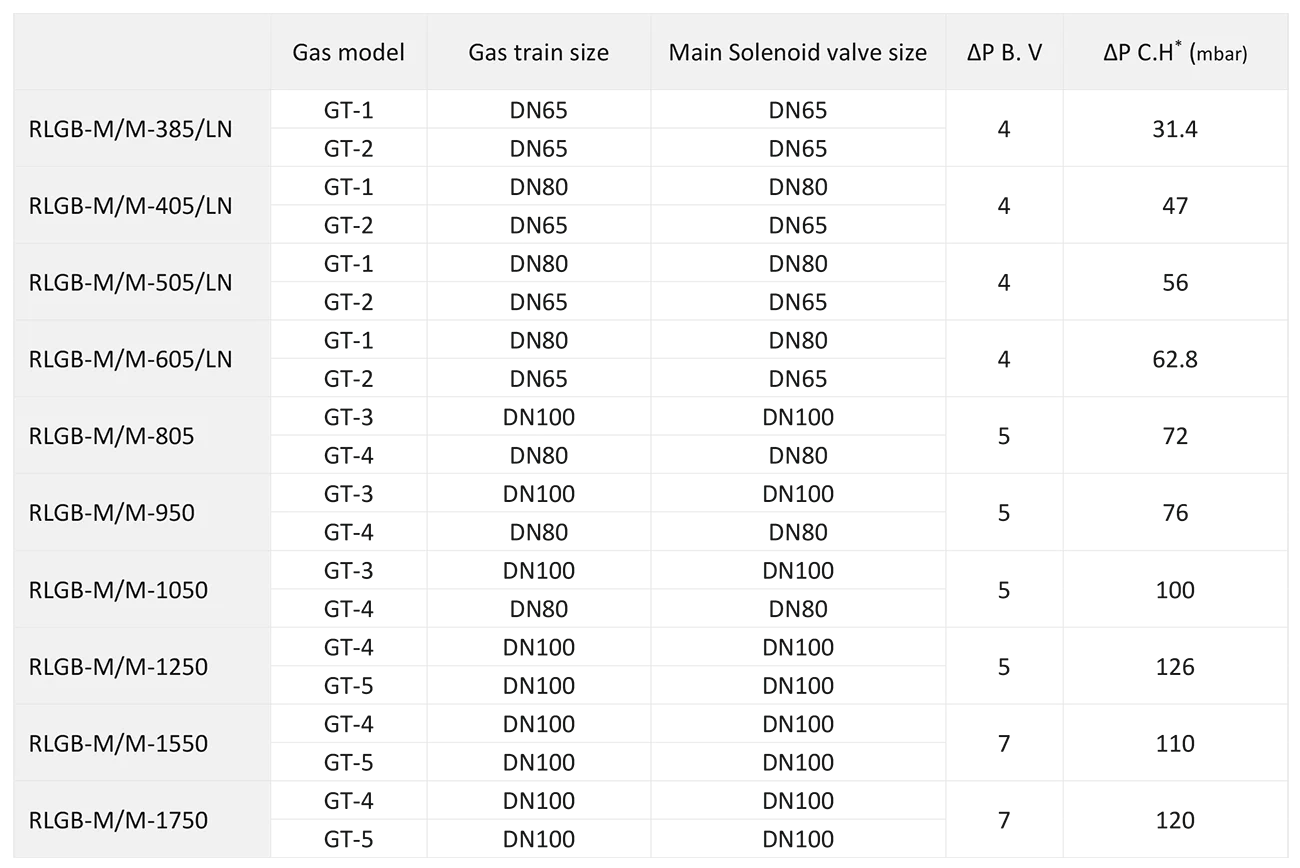

| 1: Ball Valve | 8: Safety gas valve | 14: Shut-off valve |

| 2: Gas filter | 9: Main gas valve | 15: High pressure regulator |

| 3: Push button valve | 10: Leak Test gas pressure switch | 16: Relief valve |

| 4: Pressure Gauge | 11: Max gas pressure switch | 17: Pilot regulator |

| 5: Pressure regulator (Low-pressure) | 12: Butterfly valve | 18: Pilot valve 1 |

| 6: Pressure Gauge | 13: Multi-Block Solenoid Valve | 19: Pilot valve 2 |

| 7: Min gas pressure switch |

Special Note:The above gas train sizes are proposed based on the costumer’s requests and the limits of the projects while placing an order. Therefore, we kindly ask the readers that assume this information as an initial and most likely offers.

Generally, two types of atomizing principle are utilized in Raadman modular oil burners:

All Raadman pressure based atomizing modular oil burners are equipped with a burner lance and a fly-back oil atomizer. The burner-lance is especially suitable for use in or on an oil burner and is designed to operate spill back atomizers with integrated shut-off needle. The strong spring on the actuating rod pushes the needle in closed position. This ensures a reliable shut-off under all circumstances.

Fuel, branched off from the supply line actuates the piston for opening, either controlled by two external solenoid valves or by one 3/2 solenoid valve. The piston has a fixed travel. While opening, the needle inside the atomizer is retracted in the correct position by means of a spring at the back of the atomizer against a fixed stop on the needle itself.

During the pre-purge period of the burner, the needle is keeping the orifice closed and the fuel circulates through the lance at pre-set supply and return pressure. On energizing both solenoid valves and the 3/2 solenoid valve, even after long idle intervals, there is immediate atomization guaranteeing perfect ignition.

The burner-lance is suitable for supply pressures from 20 up to 40 bar and fuel temperatures up to 140°C.

|

|

|

All Raadman air/steam atomizing modular oil burners are equipped with a special burner lance and an air/steam atomizer. The burner-lance is designed to operate 32-Y atomizers with compressed air or steam.

The strong spring on the actuating rod pushes the needle in closed position. Compressed air, controlled by an external 3/2 solenoid valve, actuates the piston for opening. The piston has a fixed travel, pulling the needle in the correct position when it opens.

During the pre-purge period of the burner, the needle is keeping the central orifice in the reverse disc closed. On energizing the 3/2 solenoid valve, even after long idle intervals, there is immediate atomization guaranteeing perfect ignition.

The burner-lance is suitable for supply pressures up to 16 bar and fuel temperatures up to 140°C.

|

|

|

Type OL-I: (Pressure based atomizer – without closing needle)

Type OL-II: (Pressure based atomizer with closing needle)

Type OL-III: (Air/Steam Atomizing technology with closing needle)

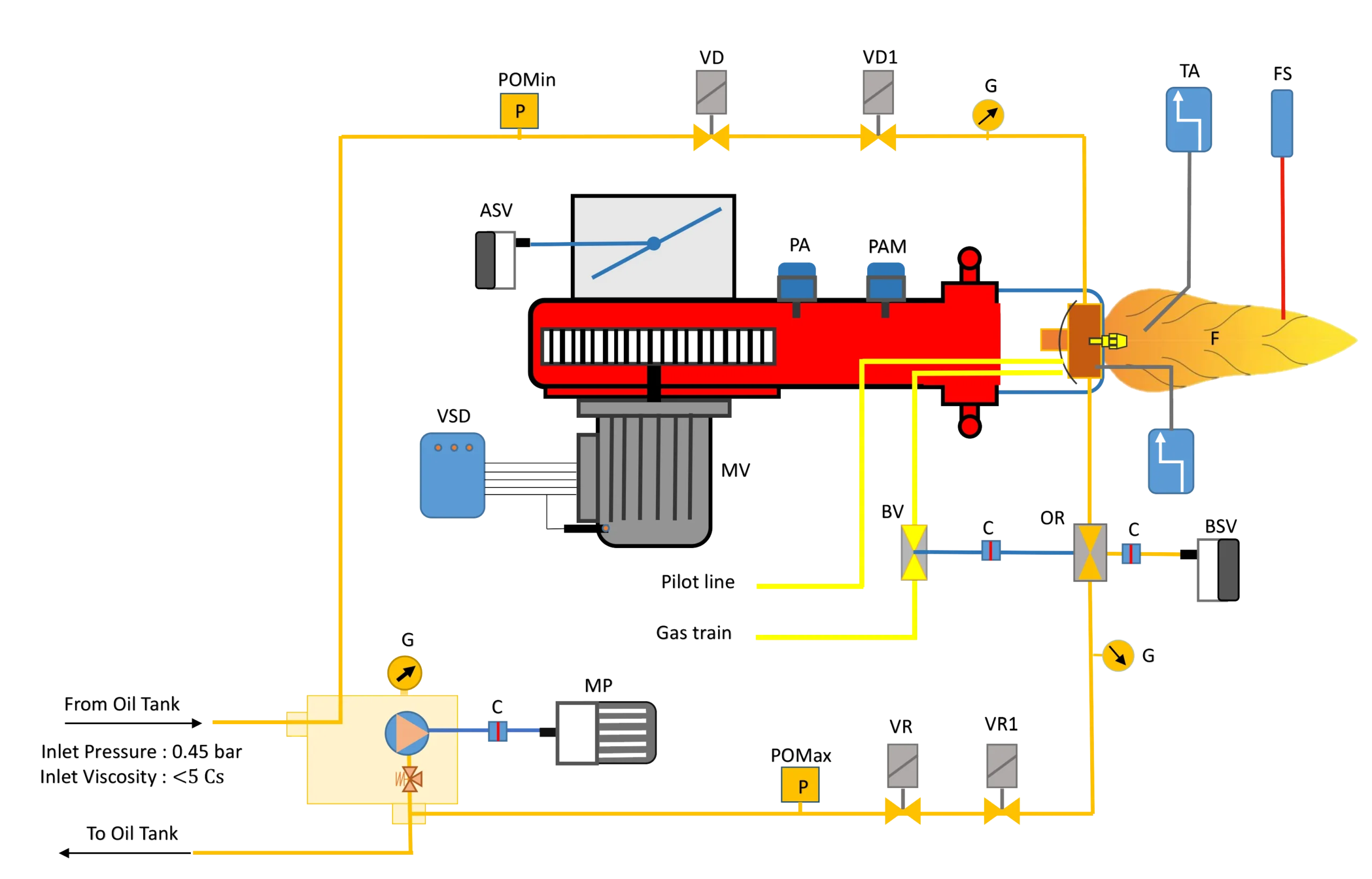

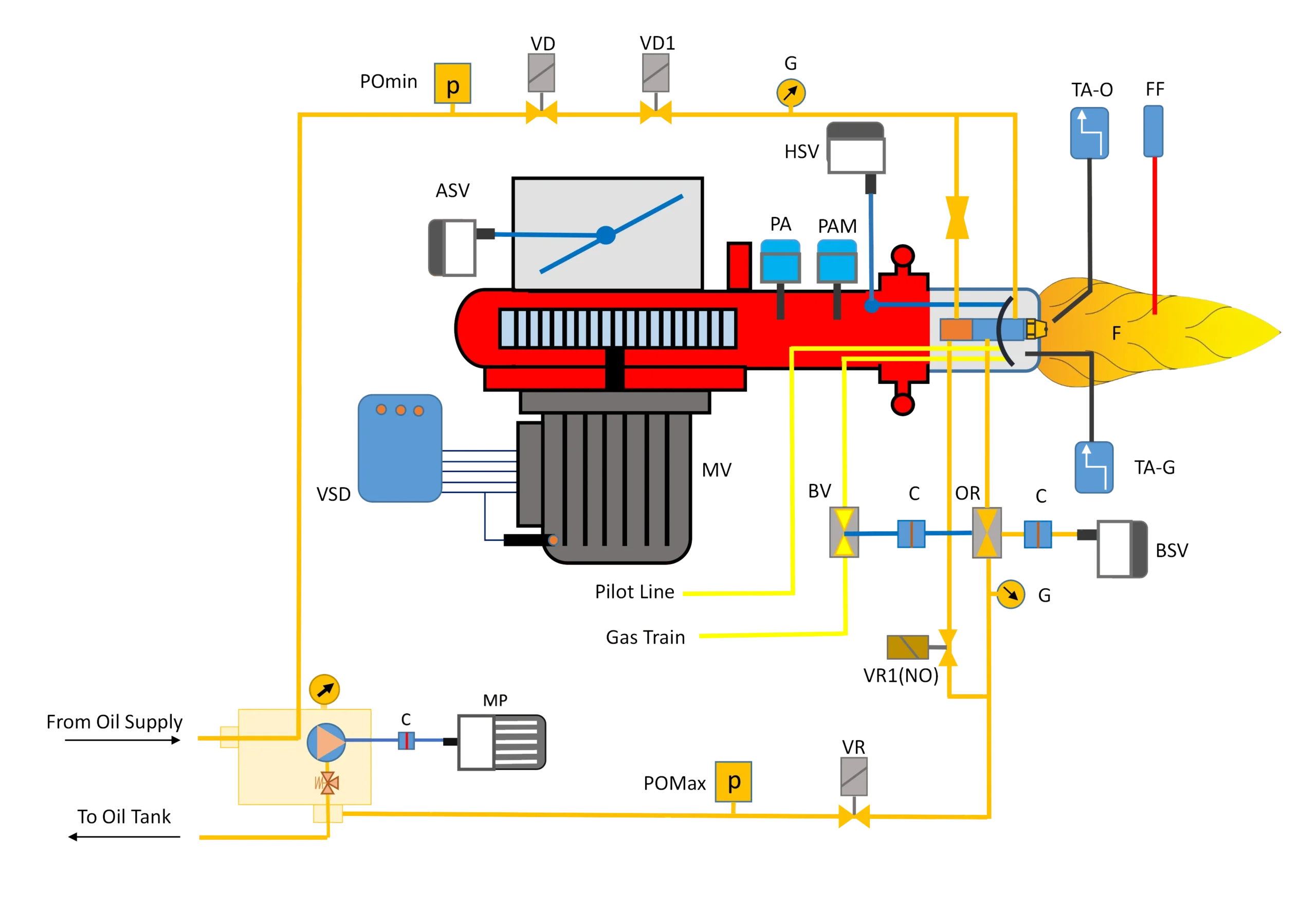

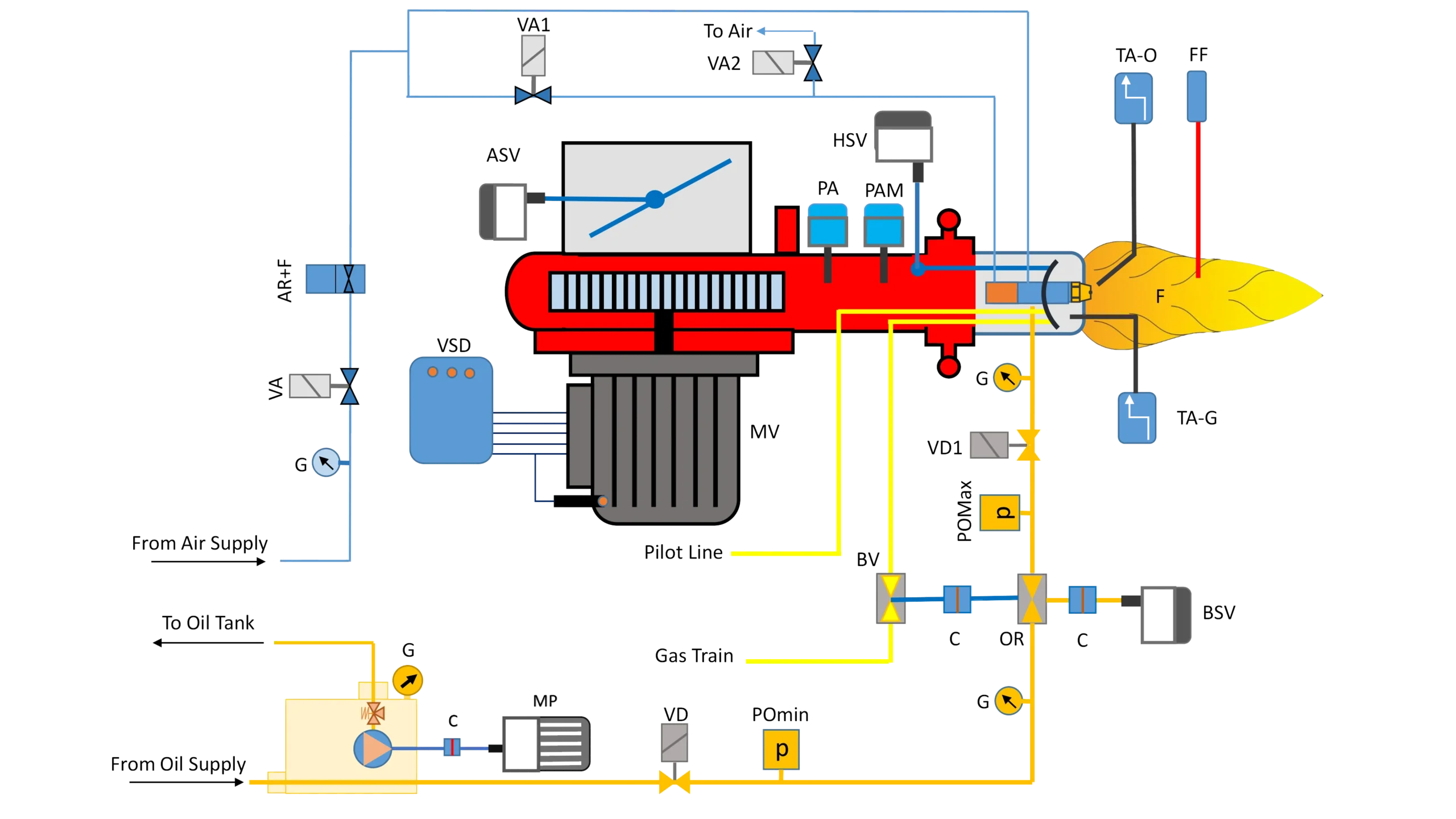

| MP: Pump motor | PA: Min. Air pressure switch | TA-G: Gas ignition transformer |

| FF: Flame sensor | PAM: Max. air pressure switch | BSV: Butterfly valve servomotor |

| VR: Return solenoid valve | POmin: Min oil pressure switch | ASV: Air damper servomotor |

| VR1: Return solenoid valve | POMax: Max oil pressure switch | HSV: Head servomotor (Optional) |

| VR1(NO): Return solenoid valve (N.O) | VA: Air Valve | BV: Butterfly valve |

| VD: Light oil safety valve (N.C) | AR+F: Air regulator and filter | OR: Oil Regulator |

| VD1: Light oil delivery valve (N.C) | TA: Flame Scanner | MV: Fan motor |

| VA1: Air solenoid valve1 | FS: Flame Sensor | VSD: Variable speed drive(optional) |

| VA2: Air solenoid valve2 | F: Gas or oil flame | C: Coupling |

| TA-O: Oil ignition transformer | G: Gauge |

PACKMAN Company was established in February, 1975. The company has started its activity in the field of producing High-Pressure Vessels such as Hot-Water Boilers, Steam Boilers, Pool Coil Tanks, Softeners and Heat Exchangers since 1984.

Newsletter