Overview of Petro-refinery burners and Their Use in Industrial Furnaces

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Refinery and petrochemical units, as critical pillars of the energy and chemical industries, depend heavily on thermal systems, particularly burners. Fired heaters are used to

Boilers serve as fundamental components in heating systems, supplying the thermal energy essential for a range of industrial and commercial applications. The burner, as the

In today’s world, energy conservation reducing environmental pollution are top priorities across various industrial sectors. Burners, as the central components of industrial furnaces and boilers,

The mechanical staging burners by raadman have a firing range from 1000 to 6200 kW, and they are manufactured by high quality electro-mechanical accessories which are easy to install and commission.

Thanks to the cam mechanism and butterfly valve, we have “Staging” operation in gas mode. In this type of burner, one actuator opens the damper and butterfly valve to reach the desired stages.

The components of these burners are as follows:

Mechanical components, burner head, flame tube, and cam mechanism, safety accessories, ignition devices, flame scanners, burner controllers such as Shokouh/Honeywell TMG or Siemens LFL, burner actuators, accessories of power system, ventilation motor, fan wheel, safety devices, and air pressure switches.

Raadman gas and dual fuel burners are suitable for the following utilization.

The following methods of regulation are available for RGB-MC and RLGB-MC Series burners:

Designed in accordance with ISIRI-7595 and ISIRI-7594 Iran national standards (equal to the BS-EN676, and BS-EN267 European standards).

Air humidity: max. 80 % relative humidity, no condensation.

The combustion air must be free of aggressive substances (halogens, chlorides, etc.) and impurities (dust, debris, vapors, etc.).

The emissions have been measured in various models at the maximum output, according to DIN-EN 676 and DIN-EN 297 standards.

The values of CO and NOx during burner operation are lower than 30 and 120 mg/kWh at 20 % excess of air for normal versions and, lower than 20 and 80 mg/kWh for Low NOx versions (LN series). Consequently, the burner’s NOx class of II and III is reported and being approved for normal version and LN Versions respectively.

LN versions (Low Nox Burners) have a higher rate of mixing during their operation. This results in a further decrease in the flame length and an increase in the flame diameter.

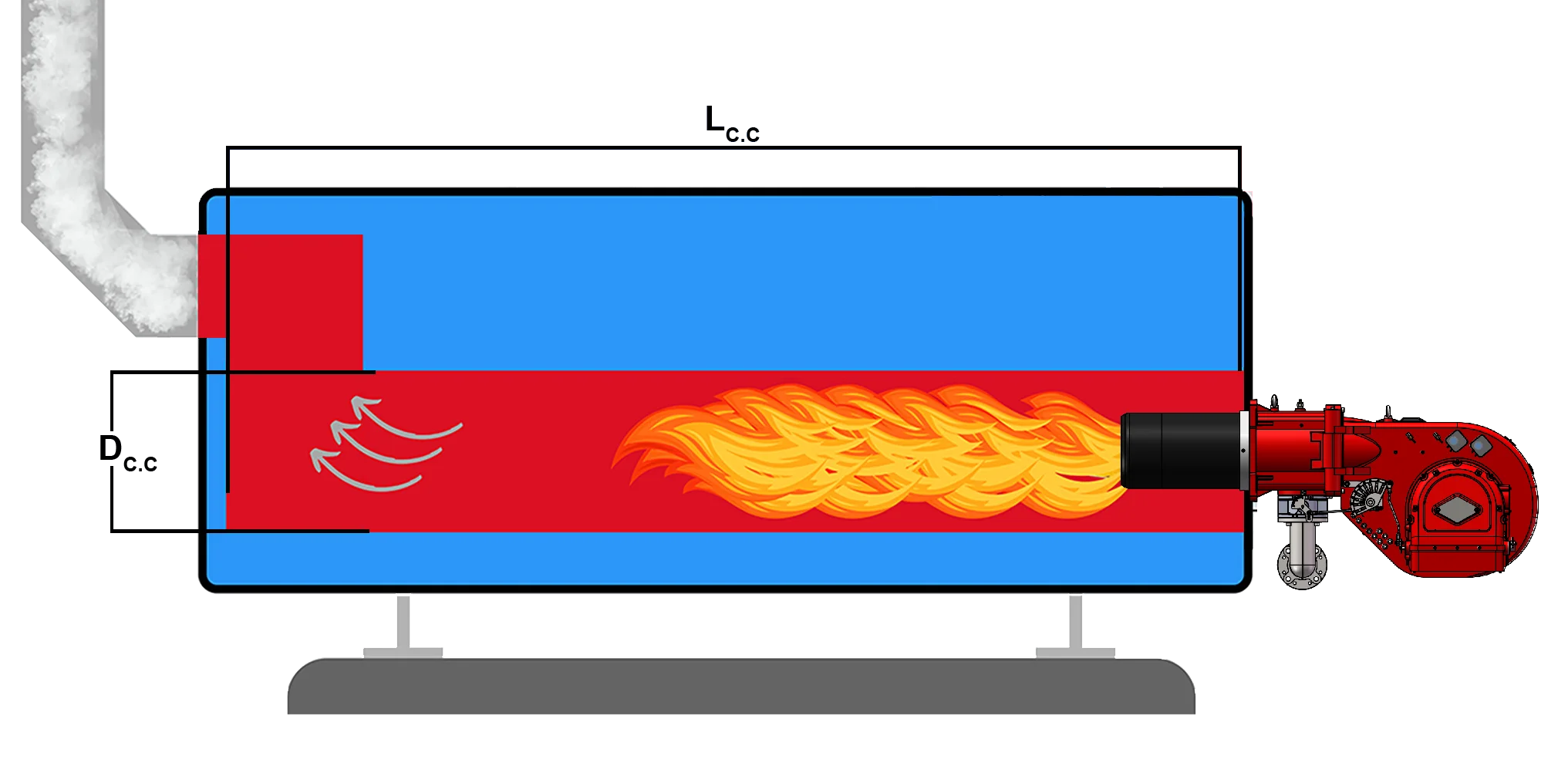

The following diagram shows the flame diameters, which have a significant impact on the burner efficiency and their compliance with the boiler combustion chamber geometry.

The Raadman burners can be appropriately selected for all boilers which are designed according to the BS-2790, BS-855, EN-303, and BS-EN 12953-3. A flame should, at its highest output, fill 90% of combustion chambers.

Newsletter