Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

Home / Premixed Burners / Page 2

premixed = premix = pre-mixed

In today’s progressive world where we live, air pollution is the most severe problem in human societies. Domestic powerhouses and burners have a significant contribution to air pollution. Dilution processes such as FGR or water and vapor injection are the latest technologies that significantly reduce NOx.

Nowadays, new premixed combustion technologies can reduce NOx and CO emissions simultaneously. You may be asked this question, what is premix combustion technology, and how does it mitigate hazardous combustion emissions?

Based on fuel and air mixing location, burners are divided into two classes: nozzle mixed and premixed burners. These burners are defined according to the BS EN 676 (2020):

Nozzle Mixed Burners: burner in which part, or all, of the air required for combustion of the gas, is mixed with the gas at, or downstream of, the air and gas ports.

Premixed Burners : burner in which part, or all, of the air for complete combustion of the gas, is mixed with the gas upstream of the mixture outlet ports.

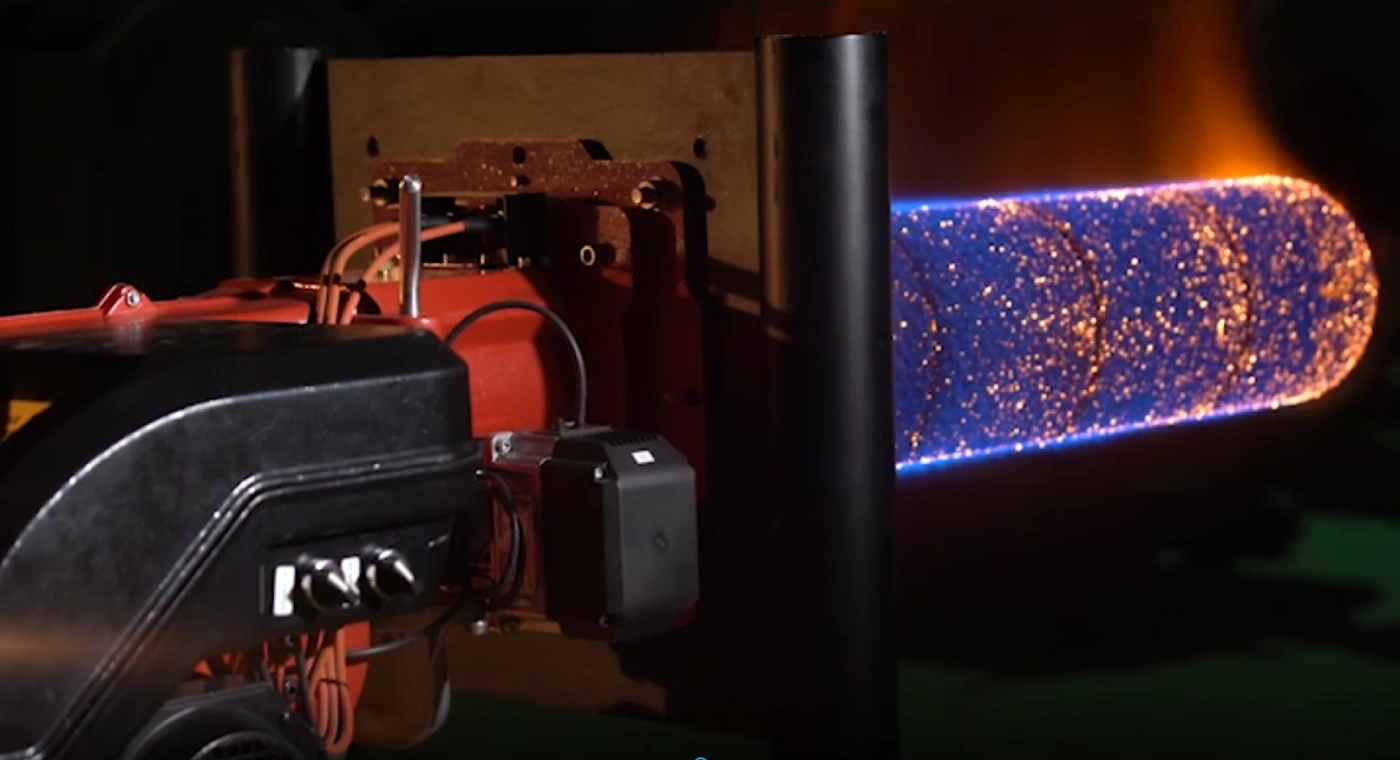

For example, air and gas are thoroughly mixed before the burner head in premixed burners. Then, the mixture goes through high-temperature stain steel, ceramics, and metal fiber heating heads. Because air and gas are mixed thoroughly, the premix burners are categorized as ultra-low NOx burners, and the CO emission value is approximately zero. Thus, they are widely adopted in residential and commercial utilizations.

The mixing process can occur before the burner’s fan in a venturi device called premixed burners or PE Series or after the burner’s fan by a cascading twisting mixing device, named post-mixed burners or PM Series. Since the mixed bulk is potentially explosive, using explosion-proof fans (or ventilators) is mandatory in premixed burners.

In «premixed burners», the pneumatic modular system (or pneumatic principle) with Pulse Width Modulation (PWM) signal controls the ratio of air/gas mixtures. While, in post-mixed burners, electrical modulating controls can quickly be hired for controlling the burner operation. It is much more straight than an electrical modular burner, using two (or more) independent actuators, has more ability to precisely control the burner, and has many advantages such as 999 points of managing the entire firing range, error monitoring, remote control, valve proving system, etc.

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and

During the last century, Nitrogen oxide emissions, called NOx, have constantly been increasing. Due to the destructive effects of nitrogen oxides on the health of

The «furnace industry» and products determine the type of flame contact. In many heat treatment processes, where the combustion gases must not come into contact

Today, high fuel consumption and environmental pollution are serious problems, especially in industrial societies. The combustion industry plays a significant role in stated pollutants.

For more than one decade, PACKMAN Low NOx burners have been used on a wide variety of heat generators and industrial plants. Currently, PACKMAN delightfully introduces new generation of Ultra Low NOx pre-mixed as well as post mixed burners known as PB-Series.

The Raadman Premix burner series is applied wherever the very lowest emission levels are being demanded. A further advantage of this type of combustion system is that it can be utilized on appliances with particularly small combustion chambers.

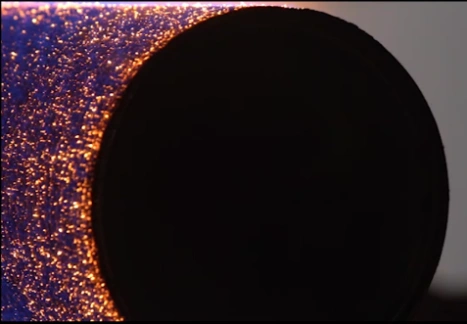

Fiber metal heating head is made of a steel chamber with a coating of metal fibers. Metal fibers are manufactured fibers composed of pure metals and metallic alloys which can be processed into textile products, porous media, plastic-coated metals, etc.

Fiber metal heating head is made of a steel chamber with a coating of metal fibers. Metal fibers are manufactured fibers composed of pure metals and metallic alloys which can be processed into textile products, porous media, plastic-coated metals, etc.

This permeable thermal coating releases most of the heat transfer through the radiation mechanism, part of which radiates from the hot surface of the thermal head and the other part from the radiation of hot combustion gases. These heating heads are produced in different ways; two of the most common production methods are weaving fibers and vacuum forming.

Raadman burners have always been particularly efficient and environmentally friendly.

Raadman burners have always been particularly efficient and environmentally friendly.

Premix burner technology is used to achieve NOx emissions below 15 ppm and even lower. Premixing followed by surface-stabilized combustion has been state of the art for many years in small condensing boilers. It is environmentally friendly, reliable and efficient. Extending these benefits to typical heat generators with larger outputs was the developmental goal for the PB burner series. Special gas/air mix Stabilized surface combustion relies on a homogeneous gas/air mixture. For that reason, a completely new mixing assembly was developed for the PB burner series. A key feature in post mixed burner is the separated feed of gas and air; the two media are not mixed together upstream of the burner head. A uniform mixture is created by the gas flow through the distributor and the combustion air that has been set in rotation by the swirl plate.

An important feature of these thermal heads is their rapid cooling process, which will occur only a few seconds after the burner is getting turned off during the post-purge period.

An important feature of these thermal heads is their rapid cooling process, which will occur only a few seconds after the burner is getting turned off during the post-purge period.

The orifices of these types of burner heads are approximately 150 microns. Therefore, the combustion air must be cleaned of dust and particles. For this reason, a 50 microns filter is suggested to be applied at the entrance of the burner air damper. If the orifices become clogged, the temperature rises dramatically and causes head failure.

In addition, excess air plays a critical role in their life span. Even though they could last for 7-10 years in sufficient excess air condition, they would last only 20000 hours in low excess air.

Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners Premixed Burners

PACKMAN Company was established in February, 1975. The company has started its activity in the field of producing High-Pressure Vessels such as Hot-Water Boilers, Steam Boilers, Pool Coil Tanks, Softeners and Heat Exchangers since 1984.

Newsletter