Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and the need

Share This Post

How much is the maximum capacity of the biggest #monoblock #burner you have ever seen?

Today, we plan to announce a new release of the #monoblock burners, but first I would like to discuss the above question.

Actually, while some people suppose that #monoblock #burners are more efficient in the material, occupied space, etc., others support the #dualblock versions because of some side positive benefits such as more compatibility with different #combustion chamber resistance, easier transportation, etc.

On the one hand, #monoblock #burners, in general, have a lighter weight and smaller geometry. This means it is necessary to consume little material in their production which, as a chain, can help our environment and #sustainability. In addition, because of an integrated body, they have a lower air pressure loss inside the body, I mean between the fan wheel and burner head, and, as a consequence, they can reach the nominal rating values by lighter/smaller #impeller and electric motor. This can save #electrical #energy which is a crucial subject these days. Assuming the whole part of a #burner close together, a smaller motor and #impeller reduce the #noise level and decreases the values of the burners total sound #power. In comparison with #dualblock #burners, the #monoblock versions occupy little space in the #boiler rooms, which helps the customer to have better maneuverability around the #heat #generators. However, it is worth remembering that manufacturing big #monoblock burners needs a professional approach in all processes of #manufacturing.

On the other hand, since in #dualblock #burners, the #combustion sections are separated from air #ventilation blocks, the weights and geometry are somehow divided, which results in a better arrangement in #stocking procedures, #lifting, and #transportations. By a separated ventilation system, #dualblock #burners can work in a wider range of heating and #steam #generators. In other words, by changing the fan side, the burners can overcome even higher #resistance in the #combustion #chambers. Air #preheating is also easier because they have better compatibility for #preheater connections or ducts. As the most powerful and the most superior advantage, in #dualbloc burners, the air side can be installed in anywhere or any direction which could help the engineers to manipulate the #boiler room accessories more effectively. However, as the #ventilations system is designed to be put at a longer distance, the pressure loss would rise accordingly. #Dualblock #burners can also be used for #multiburners applications. In other words, a number of these burners can be supplied by an integrated ventilation system, which is more applicable in large industrial applications such as oil and #powerplant projects.

All in all, we suppose there is no predefined answer if we should select the #monobloc type or the #dualblock versions. In other words, the #capacity, #application, conditions of the project, etc. can affect the final decision. In our opinion, #monoblock burners can have some priorities till the time they are planned to be chosen as the combustion system of a single #burner application. This, by an efficient consideration, will preserve our planet for the next generation in a multi-direction.

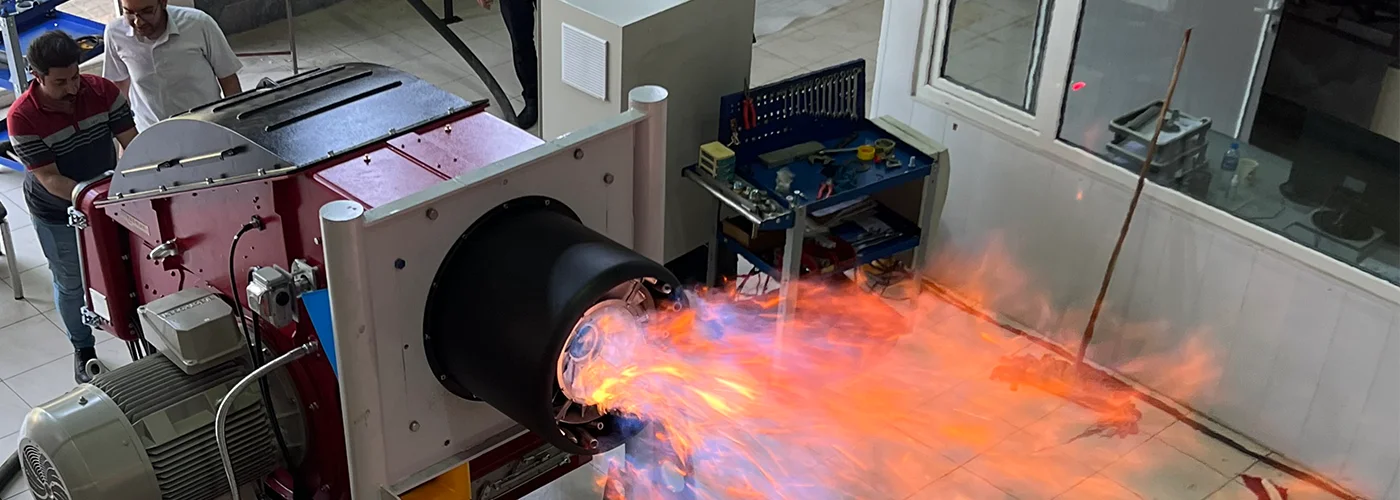

By the way, as a very strong and powerful approach in #manufacturing, Raadman burner factory is proud to share some pictures of two 22 MW monoblock burners with the ability to work with #Naturalgas, #LPG, and #lightoil. Thanks to Autoflame Engineering Limited combustion system, the burner will work in full modular operation with further safety monitoring devices such as air/gas pressure sensors.

We can highlight the #manufacturing of the #optimized #impeller with 75 kW electric motor, large burners head with movable internal accessories, big air #damper with minimum #vibration, integrated oil accessories devices by being arranged on the body and small total size of the burners as the most privileges of these burners. We should all remember that in large and heavy #burners, designing a suitable #CG, hanging procedures, and even, however, looks simple, high-quality #packing can be a critical stage and can affect the final results dramatically.

Again, and like always, we would like to thank all the genius colleges in the sales department, R&D department, solid mechanics offices, #Manufacturing Hall, Assembly sections, documents preparation sections, laboratory, logistics, etc. for the hard work and the most collaborative approach to help this forwarding step happen!

Related Article

Methods of Optimizing Boiler Efficiency and Reducing NOx Emission

The article explores NOx pollution from fossil fuel combustion, advocating Flue Gas Recirculation (FGR) for up to 50% reduction. It highlights sources, FGR benefits, and the need

During the last century, Nitrogen oxide emissions, called NOx, have constantly been increasing. Due to the destructive effects of nitrogen oxides on the health of society and

The «furnace industry» and products determine the type of flame contact. In many heat treatment processes, where the combustion gases must not come into contact with the

PACKMAN Company was established in February, 1975. The company has started its activity in the field of producing High-Pressure Vessels such as Hot-Water Boilers, Steam Boilers, Pool Coil Tanks, Softeners and Heat Exchangers since 1984.

Newsletter